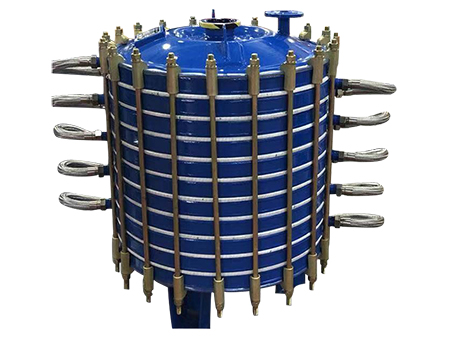

Glass Lined Plate Condenser

Glass Lined Chemical Processing Equipment

Our glass-lined steel condenser is effective anti-corrosion process equipment designed to adapt to demanding requirements of cooling and condensation processes. This glass-lined equipment is constructed using newly developed molds and undergoes sophisticated welding process, ensuring exceptional sealing effect and internal load bearing capacity without leakage while delivering simple operation and high work efficiency.

Furthermore, the glass lining of the plate type condenser guarantees exclusive corrosion resistance, enabling it capable of handling a number of corrosive substances during the operation. As an experienced manufacturer of glass-lined process equipment, we adopt advanced German technical enamels to meet the rigorous demands of chemical processing applications. In addition, the utilization of cold spraying technology ensures the coating quality, efficiently avoiding problems that often occur with thermal spraying method.

Whether used in chemical, pharmaceutical or other industrial applications, this glass-lined steel condenser can be a reliable and effective solution to handle various corrosive environments.

Design Pressure Vessel: Full Vacuum (FV) to 0.1Mpa

Jacket: ≤0.3MPa

Design Temperature 200°C

Standard HG/T4298-2019

| Item | Common plate condenser | Porous plate condenser | ||||

| P0.5 | P1 | P2 | w-0.63 | w-1 | w-2 | |

| Heat exchange rate | a | a | a | 1.5a | 1.5a | 1.5a |

| Height of water interlayer | 54 | 58 | 64 | 19 | 21 | 25 |

| Water overflow speed | Slow | Slow | Slow | Very fast | Very fast | Very fast |

| Traverses baffle (N/A) | Null | Null | Null | Available | Available | Available |

| Scaling tendency | Easy | Easy | Easy | Not easy | Not easy | Not easy |

| Type of gasket | A II | A II | A II | A I | A I | A I |

| Thickness of gasket (mm) | 30 | 30 | 30 | 10 | 10 | 10 |

| Vacuum resistance | Low | Low | Low | High | High | High |

| Warranty | Half year | Half year | Half year | One year | One year | One year |

| Enamel | Common | Common | Common | Imported | Imported | Imported |

| Total height | High | High | High | Lower | Lower | Lower |

Note: The material of type I gaskets is non-asbestos fiberboard and wavy rings coated with PTFE; type II is NBR coated with PTFE.

Common glass lined plate condenser- Due to the smaller pore opening (crossed at 180°), the hydraulic resistance is increased and the air distribution is uneven, making it unfit for high vacuum use.

- Thick condensing plates that slow the flow of cooling water, scaling-prone, and low heat-exchange rate.

- Equipped with over 20mm-thick gaskets that will swell or shrink too much and has low pressure resistance, making it unfit for vacuum seal.

- Porous plate condenser is invented based on the ordinary plate condenser but without the setbacks mentioned above. Porous plate condenser can be used for vacuum distillation and as evaporation devices. The problem of leakage is solved.

- The thickness of the plates is reduced to increase the flow of the cooling water. Compared to condensers of the same size, the six-pore design evens the fluids distribution, increases the rate of heat transfer by over 30%, and avoids scaling.

- Equipped with 10mm-thick gaskets that won’t swell and shrink too much and has higher pressure resistance, fit for high vacuum seal.

- The glass lined condenser can handle corrosive media such as hydrofluoric acid, phosgene, concentrated phosphoric acid (concentration>30%, temperature >150°C, PH>12) and almost all chemicals with temperature over 100°C;

- Heat exchanging is implemented through the alternate flowing of hot air and cold water;

- Compact structure, light weight, small size;

- The parts of glass lined condenser are replaceable and some parts are reducible, preventing the downtime caused by the time waiting for the replacement of the entire machine;

- The glass lined condenser provided by Qianqiao can withstand vacuum and avoid fouling, the heat transfer efficiency of which is 30%-50% higher than that of similar glass lined steel condensers;

- Our glass lined plate type condensers are available in two models, i.e. W-0.6 and W-1, and each model is offer with option of 3 holes or 6 holes;

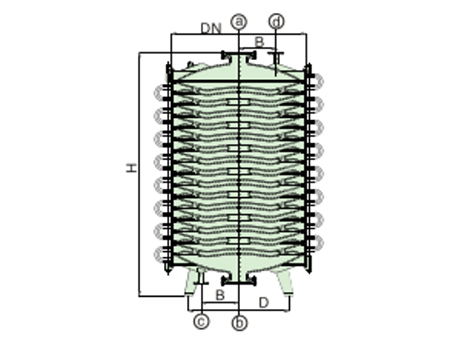

- Parts of this glass lined plate condenser include a bottom, a cap, and several condensing plates, which are assembled with gaskets, double-end stud bolts and screw nuts. Installation instructions should be followed during the assembly.

- Hot air enters the condenser through the inlet of the cap and the condensate liquid flows out through the bottom inlet. The cooling water flows in through the bottom pipe and out through the top pipe. The flow of cooling water can be controlled according to the water’s temperature difference at the overflow port and the temperature of the condenser.

- The cooling water should be neutralized to a pH value of 6-8. Otherwise, there will be scaling on the liner that causes the falling off of the glass lined layer. Water should be clean so that impurity deposition can be avoided.

- If there is any leakage during use, please fasten the nuts accordingly without over-tightening.

- It is recommended that the cooling water should be introduced prior to the hot air during use, and the flow of hot air should be stopped first when the operation is completed.

- Pressure: vessel ≤0.1Mpa, jacket ≤0.3Mpa (for any special requirements, please inform us);

- Glass lining: thermal shock 110°C, cold shock ≤100°C;

- All glass lined steel condensers are subjected to strict inspection before leaving our factory, our company is not responsible for the products that are disassembled by users themselves.