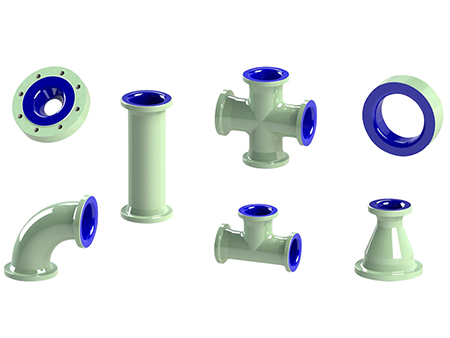

Qianqiao manufactures and offers glass lined pipes and fittings with length ranging between 100mm and 4000mm (DN25- DN2000). As crucial parts in material transmission, the glass lining can provide pipes and fittings with smooth surface while offering good chemical stability and excellent corrosion resistance against all inorganic acids, organic acids (except for hydrofluoric acid and hot concentrated phosphoric acid) and organic solvents.

Features

- All glass lined elbows go through the cold spraying process, which requires our personnel to repeat the grinding, refinement, and drying of the enamel powder. With this process, glass lined elbows feature a coating layer with uniform thickness, and the glass lined layer is closely adhered to the surface of metal piping, avoiding bubbles and preventing the coating from falling off.

- Based on the advanced glass lining technique, Qianqiao can produce glass lined piping products meeting national, European, and DIN standards.

- We have the capability to apply silicon-containing enamel to steel surface. Through approximately 900°C high temperature firing, the uniform and dense enamel layer is permanently bonded on the metal surface, thickness of the layer ranges from 0.8mm to 2mm.

- Qianqiao has established long-lasting partnership with European well-known porcelain enamel manufacturers. The reliable quality porcelain enamel supplied by these manufacturers enables our glass lined pipes and fittings to be stably used even in the harsh environments like chloroacetic acid.

Glass Lined Straight Pipes

| L | DN |

| 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 400 | 500 |

| 100 | 0.8 | 1 | 1.2 | 1.7 | 2.5 | 3.4 | 3.9 | | | | | | | |

| 150 | 1 | 1.2 | 1.4 | 2 | 3 | 3.9 | 4.8 | 6.4 | 7.9 | 12.1 | 17.4 | 21.1 | 36.6 | 46.8 |

| 200 | 1.1 | 1.4 | 1.6 | 2.2 | 3.5 | 4.5 | 5.6 | 7.5 | 9.3 | 14.2 | 20.7 | 25.0 | 41.5 | 53.5 |

| 250 | 1.2 | 1.5 | 1.8 | 2.5 | 3.9 | 5.1 | 6.5 | 8.6 | 10.8 | 16.2 | 23.9 | 28.8 | 46.4 | 60.2 |

| 300 | 1.4 | 1.7 | 2.0 | 2.8 | 4.4 | 5.6 | 7.3 | 9.7 | 12.2 | 18.3 | 27.1 | 32.7 | 51.2 | 66.9 |

| 400 | 1.6 | 2.0 | 2.4 | 3.3 | 5.4 | 6.8 | 9.0 | 11.8 | 15.0 | 22.5 | 33.6 | 40.4 | 61.0 | 80.4 |

| 500 | 1.9 | 2.4 | 2.8 | 3.9 | 6.4 | 7.9 | 10.6 | 14.0 | 17.8 | 26.6 | 40.1 | 48.1 | 70.7 | 93.8 |

| 600 | 2.2 | 2.7 | 3.2 | 4.5 | 7.3 | 9.1 | 12.3 | 16.1 | 20.6 | 30.8 | 46.5 | 55.9 | 80.5 | 107.2 |

| 700 | 2.4 | 3.1 | 3.6 | 5.0 | 8.3 | 10.2 | 14.0 | 18.3 | 23.4 | 34.9 | 53.0 | 63.6 | 90.2 | 120.7 |

| 750 | 2.6 | 3.3 | 3.8 | 5.3 | 8.8 | 10.8 | 14.8 | 19.4 | 24.8 | 37.0 | 56.2 | 67.4 | 95.1 | 127.4 |

| 800 | 2.7 | 3.4 | 4.0 | 5.6 | 9.3 | 11.4 | 15.7 | 20.4 | 26.2 | 39.1 | 59.5 | 71.3 | 100.0 | 134.1 |

| 900 | 3.0 | 3.8 | 4.4 | 6.1 | 10.3 | 12.5 | 17.3 | 22.6 | 29.1 | 43.2 | 65.9 | 79.0 | 109.7 | 147.6 |

| 1000 | 3.2 | 4.1 | 4.8 | 6.7 | 11.2 | 13.7 | 19.0 | 24.7 | 31.9 | 47.4 | 72.4 | 86.7 | 119.5 | 161.0 |

| 1200 | 3.8 | 4.8 | 5.6 | 7.8 | 13.2 | 16.0 | 22.4 | 29.1 | 37.5 | 55.7 | 85.3 | 102.2 | 138.9 | 187.9 |

| 1500 | 4.6 | 5.8 | 6.8 | 9.4 | 16.1 | 19.4 | 27.4 | 35.5 | 45.9 | 68.1 | 104.7 | 125.3 | 168.2 | 228.2 |

| 1800 | 5.4 | 6.9 | 8.0 | 11.1 | 19.0 | 22.9 | 32.4 | 42.0 | 54.4 | 80.6 | 124.1 | 148.5 | 197.4 | 268.6 |

| 2000 | 5.9 | 7.5 | 8.7 | 12.2 | 20.9 | 25.1 | 35.7 | 46.3 | 60.0 | 88.9 | 137.1 | 163.9 | 216.9 | 395.5 |

| 2500 | | | | 15.0 | 25.8 | 30.9 | 44.1 | 57.1 | 74.1 | 107.7 | 136.4 | 202.5 | 265.7 | 362.7 |

| 3000 | | | | 17.7 | 30.6 | 36.6 | 52.5 | 67.8 | 88.2 | 130.4 | 201.8 | 241.1 | 314.4 | 429.9 |

| | DN |

| 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 400 | 500 |

| 45° | A | 60 | 65 | 70 | 80 | 85 | 95 | 105 | 125 | 150 | 180 | 220 | 250 | 300 | 360 |

| R | 38 | 48 | 57 | 76 | 95 | 114 | 152 | 190 | 229 | 305 | 381 | 457 | 610 | 762 |

| daN(kg) | 0.785 | 1.1 | 1.375 | 2.075 | 2.855 | 3.28 | 4.93 | 7.6 | 11.28 | 15.36 | 22.2 | 26.69 | 32.1 | 38.28 |

| 90° | A | 99 | 117 | 113 | 141 | 167 | 153 | 120 | 130 | 272 | 247 | 294 | 345 | 446 | 548 |

| R | 62 | 80 | 76 | 102 | 128 | 114 | 193 | 228 | 229 | 203 | 254 | 305 | 406 | 508 |

| daN(kg) | 1.07 | 1.45 | 1.75 | 2.75 | 3.91 | 4.56 | 7.46 | 11.2 | 16.55 | 22.72 | 34.4 | 41.38 | 50.23 | 60.56 |

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 400 |

| L | 180 | 210 | 220 | 240 | 260 | 280 | 310 | 340 | 390 | 460 | 540 | 630 | 740 |

| L1 | 90 | 105 | 110 | 120 | 130 | 140 | 155 | 170 | 195 | 230 | 270 | 315 | 370 |

| daN | 1.98 | 2.74 | 3.39 | 4.85 | 6.72 | 8.29 | 12.88 | 17.67 | 24.63 | 39.73 | 64 | 85.34 | 151.9 |

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 400 |

| L | 180 | 210 | 220 | 240 | 260 | 280 | 310 | 340 | 390 | 460 | 540 | 630 | 740 |

| L1 | 90 | 105 | 110 | 120 | 130 | 140 | 155 | 170 | 195 | 230 | 270 | 315 | 370 |

| daN | 1.98 | 2.74 | 3.39 | 4.85 | 6.72 | 8.29 | 12.88 | 17.67 | 24.63 | 39.73 | 64 | 85.34 | 151.9 |

| DN1 | DN |

| 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 400 |

| L | DaN | L | DaN | L | DaN | L | DaN | L | DaN | L | DaN | L | DaN | L | DaN | L | DaN | L | DaN | L | DaN | L | DaN | L | DaN |

| 32 | 140 | 0.9 | | | | | | | | | | | | | | | | | | | | | | | | |

| 40 | 140 | 1.3 | 140 | 1.4 | | | | | | | | | | | | | | | | | | | | | | |

| 50 | 140 | 2 | 140 | 2.1 | 140 | 2.2 | | | | | | | | | | | | | | | | | | | | |

| 65 | 150 | 2.2 | 150 | 2.3 | 150 | 2.4 | 150 | 2.5 | | | | | | | | | | | | | | | | | | |

| 80 | 160 | | 160 | 2.6 | 160 | 3.4 | 160 | 3.5 | 160 | 3.6 | | | | | | | | | | | | | | | | |

| 100 | 175 | | | | 175 | 4.3 | 175 | 5 | 175 | 5.1 | 175 | 5.4 | | | | | | | | | | | | | | |

| 125 | 200 | | | | | | 200 | 6.8 | 200 | 6.9 | 200 | 7.4 | 200 | 8.8 | | | | | | | | | | | | |

| 150 | 225 | | | | | | | | 225 | 8.7 | 225 | 8.5 | 225 | 10 | 225 | 10.5 | | | | | | | | | | |

| 200 | 250 | | | | | | | | | | 250 | 14.4 | 250 | 15.4 | 250 | 15.8 | 250 | 16.9 | | | | | | | | |

| 250 | 300 | | | | | | | | | | | | 300 | 22.5 | 300 | 22.8 | 300 | 23.6 | 300 | 25.9 | | | | | | |

| 300 | 325 | | | | | | | | | | | | | | 325 | 28.7 | 325 | 29.6 | 325 | 32 | 325 | 35.6 | | | | |

| 400 | 450 | | | | | | | | | | | | | | | | | | 450 | 44.6 | 450 | 51.3 | 450 | 55 | | |

| 500 | 600 | | | | | | | | | | | | | | | | | | | | | | 600 | 81.11 | 600 | 96.6 |

Glass Lined Casing Spacers

| L | DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 400 | 500 |

| G | 60 | 78 | 88 | 102 | 122 | 138 | 158 | 188 | 214 | 269 | 322 | 370 | | |

| 12 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.1 | 1.4 | 1.6 | 23 | 2.9 | 3.3 | | |

| 15 | 0.4 | 0.2 | 0.6 | 0.7 | 1 | 1.2 | 1.4 | 1.7 | 2 | 2.9 | 3.7 | 4.1 | | |

| 20 | 0.5 | 0.3 | 0.8 | 1 | 1.3 | 1.6 | 1.8 | 2.3 | 2.7 | 3.8 | 4.9 | 5.5 | 10.2 | 13.1 |

| 25 | 0.6 | 0.8 | 0.9 | 1.2 | 1.6 | 2 | 2.3 | 2.9 | 3.4 | 4.8 | 6.1 | 6.9 | 12.8 | 16.3 |

| 30 | 0.7 | 0.9 | 1.1 | 1.4 | 2 | 2.4 | 2.7 | 3.4 | 4.1 | 5.8 | 7.3 | 8.3 | 15.4 | 16.9 |

| 35 | 0.9 | 1.1 | 1.3 | 1.7 | 2.3 | 2.8 | 3.2 | 4 | 4.8 | 4.8 | 4.8 | 4.8 | 17.9 | 22.9 |

| 40 | 1 | 1.2 | 1.5 | 1.9 | 2.6 | 3.2 | 3.6 | 4.6 | 5.4 | 7.7 | 9.8 | 11 | 20.5 | 26.2 |

| 45 | 1.1 | 1.3 | 1.7 | 2.1 | 3 | 3.6 | 4.1 | 5.2 | 6.1 | 8.6 | 11 | 12.4 | 23 | 29.4 |

| 50 | 1.2 | 1.5 | 1.9 | 2.4 | 3.3 | 4 | 4.5 | 5.7 | 6.8 | 9.6 | 12.2 | 13.8 | 25.6 | 32.7 |

| 60 | 1.5 | 1.8 | 2.2 | 2.8 | 4 | 4.8 | 5.4 | 6.9 | 8.2 | 11.5 | 14.7 | 16.6 | 30.7 | 39.2 |

| 70 | 1.7 | 2.1 | 2.6 | 3.3 | 4.6 | 5.6 | 6.3 | 8 | 9.5 | 13.4 | 17.1 | 19.3 | 35.8 | 45.8 |

| 80 | 1.9 | 2.4 | 3 | 3.8 | 5.3 | 6.4 | 7.2 | 9.2 | 10.9 | 15.4 | 19.6 | 22.1 | 41 | 52.3 |

| 90 | 2.2 | 2.7 | 3.4 | 4.3 | 5.9 | 7.2 | 8.1 | 10.3 | 12.2 | 17.3 | 22 | 24.8 | 46.1 | 58.8 |

| 100 | | | | | | | | | | | | | 51.2 | 65.4 |

Glass Lined Reducing Flanges (PN10)

| DN | DN1 | A | E | G | DN SIDE | DN SIDE |

| K | N-φ | H |

| 25 | 15 | 115 | 35 | 68 | 85 | 4*M12 | 18 |

| 20 | 18 |

| 32 | 25 | 140 | 35 | 78 | 100 | 4*M12 | 18 |

| 40 | 25 | 150 | 35 | 88 | 110 | 4*M12 | 18 |

| 32 | 18 |

| 50 | 25 | 165 | 35 | 102 | 125 | 4*M12 | 18 |

| 32 | 18 |

| 40 | 18 |

| 65 | 25 | 185 | 35 | 122 | 145 | 8*φ18 | 18 |

| 32 | 8*M16 | 18 |

| 40 | 18 |

| 50 | 18 |

| 80 | 25 | 200 | 35 | 138 | 160 | 8*φ18 | 16 |

| 32 | 8*M16 | 18 |

| 40 | 18 |

| 50 | 18 |

| 65 | 18 |

| 100 | 25 | 22 | 45 | 158 | 180 | 8*φ18 | 18 |

| 32 | 18 |

| 40 | 18 |

| 50 | 8*M16 | 20 |

| 65 | 20 |

| 80 | 20 |

| 125 | 25 | 250 | 45 | 188 | 210 | 8*φ18 | 16 |

| 32 | 18 |

| 40 | 18 |

| 50 | 18 |

| 65 | 20 |

| 80 | 20 |

| 100 | 20 |

| 150 | 25 | 285 | 45 | 214 | 240 | 8*φ22 | 16 |

| 32 | 18 |

| 40 | 18 |

| 50 | 18 |

| 65 | 18 |

| 80 | 18 |

| 100 | 8*M22 | 24 |

| 125 | 24 |

| 200 | 25 | 340 | 45 | 295 | 295 | 8*φ22 | |

| 32 | |

| 40 | |

| 50 | |

| 65 | |

| 80 | |

| 100 | |

| 125 | 8*M22 | |

| 150 | |

| 250 | 25 | 385 | 45 | 350 | 350 | 12*φ22 | |

| 32 | |

| 40 | |

| 50 | |

| 65 | |

| 80 | |

| 100 | |

| 125 | |

| 150 | |

| 200 | 12*M22 | |

| 300 | 25 | 445 | 45 | 400 | 400 | 12*φ22 | |

| 32 | |

| 40 | |

| 50 | |

| 65 | |

| 80 | |

| 100 | |

| 125 | |

| 150 | |

| 200 | |

| 250 | |

| 400 | 25 | 565 | 45 | 515 | 515 | 16*φ27 | |

Compared to glass pipe fittings, glass lined steel pipes and fittings feature higher strength and durability, which avoids any hazards caused by fragments from glass breakage. Also, compared to PTFE lined steel pipes, the falling off of the non-metal coating layer does not happen in the glass lined pipes even in high temperature and under vacuum conditions because the glass lined layer is tightly adhered to the metal surface. Therefore, glass lined piping system is widely applied in various industries including chemical, petrochemical, pharmaceutical, dyes, pesticides, food, etc., and plays an vital role in scientific research tasks where corrosion and clean work environment are two most important criteria.