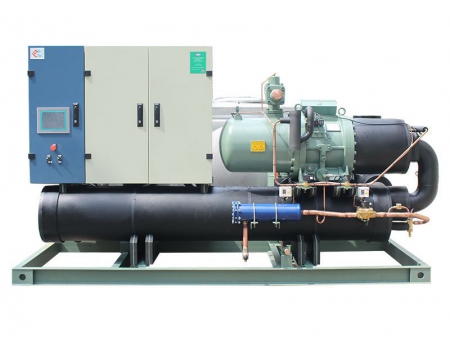

Evaporative Condenser Chiller

The evaporative condenser's refrigerant evaporates and takes in heat, while the heat generated during condensation is transmitted to the water film on the exterior of the tube. This eliminates the impact of the oil film, tube wall, and debris. The water film then evaporates and transmits the heat to the air. This evaporative condenser chiller requires less water than ordinary water-cooled or air-cooled condensers and has the benefits of low noise, a lower condensing temperature and lesser air volume in fans. It is an especially suitable cooling option for areas where water is scarce and the climate is dry.

Evaporative screw type chiller units are the energy-efficient refrigerator equipment of the moment, developed on leading international heat exchange technologies and completely taking into account the present industry trends. With its crucial advantages of unparalleled operating costs, tremendous energy savings and much lower water consumption, these chiller units have been efficiently implemented in various industries, including chemical, food processing and freezing all across the globe. On average, they are 26% more productive than traditional water cooling systems and require only around 60% of the water.

-

LOW OPERATING COSTS

This compressor system requires significantly less power than other cooling tower/condenser systems, with a 30% reduction compared to an air-cooled condenser system. Furthermore, the fan power is similar to a standard cooling tower/condenser system, while consuming a mere one-third the power required with an air-cooled condenser fan. Most notably, the pump power is roughly 25% of the pump power required with the more traditional cooling tower/condenser system.

-

SAVE SPACE AND WATER

Evaporative condensers are ideal for space-constrained environments, as they provide the same condenser function as a cooling tower/condenser system, but without taking up as much space. These condensers require only about half the area of air-cooled condensers, and use significantly less water, at just 3-5% of what water-cooled condenser systems require. Additionally, they require minimal air flow.

-

LOW INVESTMENT COSTS

The evaporative condenser combines a cooling tower, condenser, circulating pool, and circulation water pump, eliminating the need for individual components in the cooling tower/condenser system and reducing expenses associated with setup and installation. Furthermore, the evaporative cooling heat exchange method utilized by the condenser maximizes efficiency, allowing for a significant reduction in heat exchange area, fan quantity, and the amount of electricity consumed by the fan motor.

Refrigerant: R134a

Power supply: 380V-3N-50Hz

| Model | Nominal cooling capacity kW | Compressor power input kW | Compressor efficiency | Capacity control % | Refrigerant charge (excluding evaporative condenser) kg | Chilled water | Evaporative condenser | Noise level dB(A) | Total weight (including internal and external units) kg | Operating weight (including internal and external units) kg | |||||||||

| Water flow m3/h | Water pressure drop kPa | Design water pressure MPa | Pipe diameter (inlet/outlet) in | Model | Fan air flow×1000 m3/h | Water pump water flow m3/ h | Power input kW | Refrigerant charge kg | Water consumption kg/h | Weight kg | |||||||||

| 412 | 73 | 5.64 | 0, 50, 75, 100 | 92 | 71 | 68 | 1 | 4″ | SPL-735 | 87 | 70 | 9.0 | 150 | 700 | 3810 | 70 | 6340 | 8340 | |

| 543 | 96 | 5.66 | 109 | 93 | 70 | 1 | 5″ | SPL-1000 | 71*2 | 84 | 13.0 | 190 | 1000 | 4940 | 70 | 7500 | 10000 | ||

| 680 | 118 | 5.76 | 140 | 117 | 70 | 1 | 5″ | SPL-1285B | 78*2 | 150 | 14.0 | 250 | 1300 | 6090 | 73 | 9090 | 13540 | ||

| 823 | 141 | 5.84 | 179 | 142 | 72 | 1 | 6″ | SPL-1490 | 87*2 | 150 | 18.0 | 310 | 1500 | 7070 | 74 | 10820 | 14190 | ||

| 964 | 166 | 5.81 | 191 | 166 | 74 | 1 | 6″ | SPL-1765C | 71*3 | 180 | 20.5 | 320 | 1800 | 8050 | 76 | 12000 | 17000 | ||

| 1226 | 211 | 5.81 | 216 | 211 | 74 | 1 | 8″ | SPL-2245 | 87*3 | 180 | 26.5 | 460 | 2300 | 9790 | 78 | 14500 | 21500 | ||

| 1570 | 262 | 5.99 | 264 | 270 | 76 | 1 | 8″ | SPL-2830 | 125*3 | 233 | 38.5 | 520 | 2900 | 11090 | 78 | 16500 | 23500 | ||

| 1821 | 302 | 6.03 | 310 | 313 | 76 | 1 | 8″ | SPL-3470 | 100*4 | 233 | 35.5 | 680 | 3500 | 14540 | 80 | 20540 | 27500 | ||

| 1928 | 332 | 5.81 | 383 | 332 | 78 | 1 | 10″ | SPL-3740 | 125*4 | 233 | 49.5 | 680 | 3800 | 14580 | 80 | 21500 | 28540 | ||

| 2452 | 422 | 5.81 | 435 | 422 | 78 | 1 | 10″ | SPL-4420 | 125*4 | 286 | 51.5 | 820 | 4000 | 15740 | 82 | 23740 | 31740 | ||

| 3140 | 524 | 5.99 | 528 | 540 | 80 | 1 | 10″ | SPL-5520 | 125*5 | 286 | 62.5 | 1000 | 5000 | 19300 | 84 | 28300 | 39300 | ||

| 3642 | 604 | 6.03 | 625 | 626 | 82 | 1 | 12″ | SPL-6000 | 125*5 | 286 | 62.5 | 1250 | 6000 | 21300 | 84 | 31300 | 41800 | ||

Notes:

- 1. Rated cooling capacity standard: air dry / wet bulb temperature 35℃ /24℃, chiller water inlet/outlet temperature 12℃ /7℃, fouling factor 0.088 ㎡•℃ /kW;

- 2. Chiller water temperature range: 5℃ ~20℃;

- 3. Ambient temperature range: 15℃ ~43℃

- A massive improvement in energy efficiency with 85% savings over water-cooled types.

- Save a massive 30% or more on water system pipeline engineering costs, and lighten the burden of on-site workload.

- When the temperature is high, the refrigeration capacity enhances by 15%, making it optimal for the summer months when the ambient temperature peaks.

- Under winter conditions of low temperatures, freezing in water towers is successfully prevented. The evaporative pipeline is insulated to ensure no ice buildup, whilst simultaneously ensuring the towers do not become saturated with water.

- An evaporative condenser is a highly efficient, water-and-fluorine-based heat exchange device with air-cooled design as well, which proves to offer superior thermal performance.

- The evaporative condenser combines elements of the traditional chiller, shell and tube condenser, cooling tower and water pump, as well as related connection pipeline and valves, into a single unit.