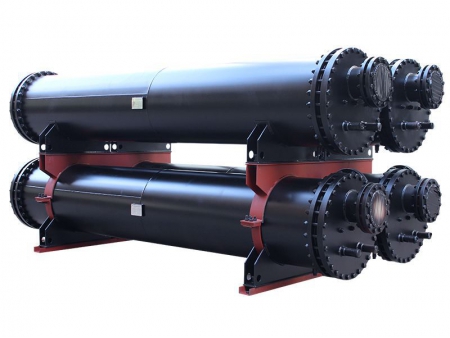

Shell and Tube Dry Expansion Evaporator

Choose an upgraded shell and tube dry expansion evaporator with improved features. This evaporator ensures high performance with its thickened internal thread pipe and spiral baffle plate that creates a channeling flow within the waterway. As a result, the evaporator is now more compact and boasts elevated heat transfer efficiency - all while being compatible with any type of compressor. Get the most out of your refrigerant pipe evaporation and waterway shell refraction with this revolutionary design.

Refrigerant goes through the dry expansion heat exchange tube, while cold water runs on the outside. The efficiency of the exchanger, however, isn't very high and its coefficient of heat exchange is only around two times that of the tube heat exchanger. Nevertheless, it is quite simple to use and control, plus it requires a cooling capacity of just 1/2 to 1/3 compared to the more common flooded unit.

The dry expansion evaporator provides a reliable and efficient means of managing the air conditioning needs of any space, allowing liquid refrigerant to be quickly and effectively converted to a vapor and subsequently frozen into chilled water. This chilled water then powers the air conditioning system, ensuring optimal temperature control and comfort.

Our product line offers an impressive capacity range, with options of 12096kcal/h up to an incredible 1587600kcal/h, all customizable to your specific needs.

- A vacuum environment heated and dried to high temperatures in the dry evaporator refrigerant tube eliminates all other contaminants and moisture.

- Utilising copper tubes of the highest grade and with a ribless construction, the dry expansion evaporator copper tube is especially resilient against corrosion and unlikely to rupture.

- After undergoing ultra-high pressure hydraulic or mechanical pipe rising, the fins of the dry expansion evaporator are held close to the copper tube, creating a tight seal and allowing for highly efficient heat exchange.

- Crafted with supreme quality steel that resists corrosion, the dry evaporator outer frame end plate is notable for its exceptional strength and straightforward assembly.

- To meet design flow rate needs, we've implemented both a single or a dual loop system. The internal circuit of the dry evaporator is highly efficient, with minimal water resistance and excellent heat exchange capability.

- Without the need for an oil return device, the lubricating oil can be returned back to the compressor.

- The dry expansion evaporator utilizes only one-third of the normal quantity of refrigerant, yet its cooling capacity remains the same as a flooded evaporator.

| Model | Nominal heat exchange capacity kW | Water inlet/outlet inch | Refrigerant inlet inch | Refrigerant outlet inch | Length A mm | Width B mm | Height C mm | Weight kg | ||

| R22 | R134A | R407C | ||||||||

| | 18 | 14 | 16 | 1" | 5/8〞 | 7/8〞 | 835 | 310 | 235 | 58 |

| | 28 | 23 | 25 | 1-1/2〞 | 7/8〞 | 1-3/8〞 | 986 | 310 | 235 | 62 |

| | 35 | 28 | 32 | 2" | 7/8" | 1-3/8" | 986 | 310 | 235 | 76 |

| | 49 | 39 | 44 | 2" | 1-1/8" | 1-5/8" | 1286 | 310 | 235 | 105 |

| | 70 | 56 | 63 | 2" | 1-3/8" | 2-1/8" | 1584 | 310 | 235 | 121 |

| | 88 | 70 | 79 | 2" | 1-3/8" | 2-1/8" | 1834 | 310 | 235 | 136 |

| | 106 | 84 | 95 | 2-1/2" | 1-3/8" | 2-1/8" | 1934 | 390 | 280 | 145 |

| | 123 | 98 | 111 | 2-1/2" | 1-3/8" | 2-1/8" | 1934 | 390 | 280 | 154 |

| | 141 | 113 | 127 | 2-1/2" | 1-3/8" | 2-5/8" | 1934 | 390 | 280 | 164 |

| | 158 | 127 | 142 | 2-1/2" | 1-3/8" | 2-5/8" | 1934 | 390 | 280 | 175 |

| 70 | 56 | 63 | 2" | 1-3/8" | 2-1/8" | 1934 | 390 | 280 | 151 | |

| 88 | 70 | 79 | 2" | 1-3/8" | 2-1/8" | 1934 | 390 | 280 | 157 | |

| 106 | 84 | 95 | 2-1/2" | 1-3/8" | 2-1/8" | 1934 | 390 | 280 | 163 | |

| 123 | 98 | 111 | 2-1/2" | 1-3/8" | 2-1/8" | 1934 | 390 | 280 | 169 | |

| 141 | 113 | 127 | 2-1/2" | 1-3/8" | 2-5/8" | 1934 | 420 | 340 | 226 | |

| 158 | 127 | 142 | 2-1/2" | 1-3/8" | 2-5/8" | 1934 | 420 | 340 | 232 | |

| 176 | 141 | 158 | 2-1/2" | 1-3/8" | 2-1/8" | 1934 | 420 | 340 | 238 | |

| 193 | 155 | 174 | 2-1/2" | 1-3/8" | 2-1/8" | 1934 | 420 | 340 | 244 | |

| | 176 | 141 | 158 | 2-1/2" | 1-3/8" | 3" | 2253 | 420 | 340 | 299 |

| | 193 | 155 | 174 | 2-1/2" | 1-3/8" | 3" | 2253 | 420 | 340 | 311 |

| | 211 | 169 | 190 | 2-1/2" | 1-3/8" | 3" | 2253 | 420 | 340 | 323 |

| | 229 | 183 | 206 | 3" | 1-3/8" | 3" | 2653 | 420 | 340 | 328 |

| | 246 | 197 | 222 | 3" | 1-3/8" | 3" | 2653 | 420 | 340 | 342 |

| | 264 | 211 | 237 | 3" | 1-3/8" | 3" | 2653 | 420 | 340 | 354 |

| | 281 | 225 | 253 | 3" | 1-3/8" | 3" | 2653 | 420 | 340 | 366 |

| | 299 | 239 | 269 | 3" | 1-3/8" | 3" | 2653 | 420 | 340 | 370 |

| 211 | 169 | 190 | 2-1/2" | 1-3/8" | 3" | 2653 | 420 | 340 | 300 | |

| 229 | 183 | 206 | 3" | 1-3/8" | 3" | 2653 | 420 | 340 | 312 | |

Notes:

- 1. Rated heat exchange parameters: evaporation temperature Te=2 ℃, inlet water temperature Ti=12 ℃, outlet water temperature To=7 ℃, overheat temperature 5 ℃.

- 2. Water source working condition parameters: evaporation temperature Te=3 ℃, inlet water temperature Ti=15 ℃, outlet water temperature To=8 ℃, overheat temperature 5 ℃. Heat exchange Q (water source) = 1.05Q (rated).

- 3. Refrigerant side max. allowable working pressure: 3.0 MPa, operating pressure: 2.5 MPa; water side max. allowable working pressure: 2.0 MPa.

- 4. Water pressure drop < 100 KPa.

Standard copper tube

Suitable for domestic water, non-toxic and neutral water, and neutral alcohol solutions.

Nickel-copper tube

Known as nickel cupronickel, nickel-copper tube is suitable for use in seawater, river water, calcium chloride solution, ethylene glycol solution and other near-neutral pH solutions without sulfide contamination.

Aluminum brass tube

Often referred to as naval brass, aluminum brass tube may be used with river water, calcium chloride solutions, ethylene glycol solutions and in sea-water without sulphide contamination.

304/316L stainless steel tube

Suitable for corrosive environments that contain salts, inorganic acids, organic acids, alkalis, or other harmful substances. Cannot be used in solutions with chloride compounds.

Titanium tube

Titanium tube has unparalleled corrosion resistance in acidic, alkaline, and neutral saline solutions; it far surpasses the corrosion resistance of stainless steel as well as other non-ferrous metals.