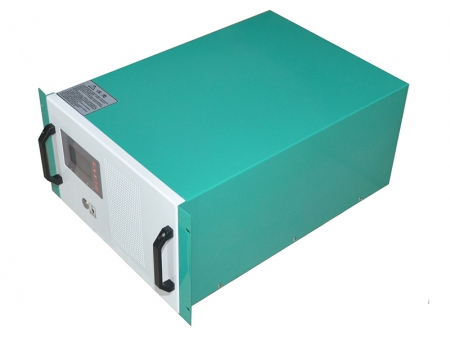

Inverter Welding Power Supply Unit

Request a Quote

Inverter welding power supply unit uses a closed-loop feedback control mode for inverter micro-spot welding power supply. The integrated structure of the fuselage improves the welding precision, making it suitable for LCP hot riveting, FPC substrate welding, and more.

The machine is used in the production of, or processes involving the following products:- LCP hot riveting

- FPC substrate

- Pulse discharge up to 9 times

- According to the technological requirements, different control modes such as constant current and constant voltage can be chosen.

- It displays real-time dynamic waveform of current-voltage-resistance-power-heat at the same time, which is convenient for welding quality management.

| Model | IPS-10A | |

| Current output type | Front panel output | |

| Rated power(KVA) | 1.9 | |

| Inverter working frequency | 4 | |

| Maximum short-circuit current(A) | 1000 | |

| Secondary No-load voltage (V) | 6.1 | |

| Maximum utilization rate | 5% (output 1000Ah) | |

| Welding order setting (15 groups) | Pre-load (SQZ) | 0~9999 |

| Rise I (RISE1) | 0~999 | |

| Weld I (WELD1) | 0~999 | |

| Cool (COOL) | 0~999 | |

| Rise II (RISE2) | 0~999 | |

| Weld II (WELD2) | 0~999 | |

| Load hold (HOLD) | 0~9999 | |

| Monitoring range setting | Current (A) | 100~1000 |

| Voltage (V) | 0.10~3.00 | |

| Power (W) | 0~9999 | |

| Resistance (mΩ) | 0~9.99 | |

| Welding pulse times | 0~9 | |

| Welding points counter | 0 ~ 99999 | |

| Current uprush adjusting function | Yes (1~9 level) | |

| Alarm function status output function | over-current, over-voltage, over-heat, no-current, preparation done, NG, GOOD, count full, stage-up full, over | |

| Weight (kg) | 15 | |

| Dimension (L*W*H)(mm) | 400×300×200 | |

| Current input | single phase AC220V±10%、50/60HZ | |

| | ||

Related

robotic welder parts, resistance welding, industrial power supply

robotic welder parts, resistance welding, industrial power supply

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos