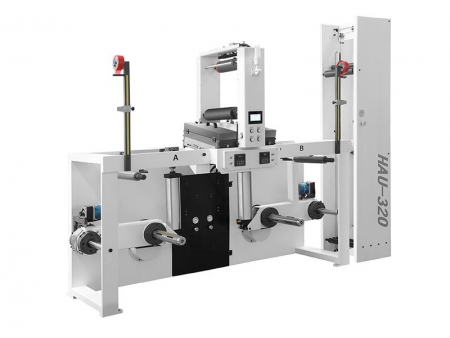

Non-Stop Unwinder, HUA-350A/B

Automatic unwinding and butt splicing machine for label, film and paper rolls

The non-stop unwinder is a machine that connects two rolls of material together. It usually joins the end of one roll to the start of another. The non-stop unwinder trims and aligns the ends automatically to avoid overlap. A thin adhesive tape secures the joint at the top, bottom, or both ends. This technique is important to prevent excessive thickness where the rolls overlap. The DABA automatic splicer can perform this task without slowing down or halting production.

In label production lines, the unwinder works with printers and die-cutters, reducing the need for manual unwinding. This saves on labor and time costs and significantly boosts production capacity.

All rolls including non-woven fabrics, plastic films, paper, aluminum foils, etc.

- The unwinder is equipped with a stable tension control system using piecewise tension coupling.

- The built-in roll handling system lifts rolls weighing up to 500 KGS with no need for auxiliary rollers, plus easy to control.

- The unwinder accommodates two full-diameter rolls at any time.

- Equipped with roll cutting and splicing device that is reliable and easy-to-control, facilitating clean cutting and tight splicing.

- 10-degree angle for material splicing with tape on both sides (diagonal connection).

- Fully automatic side guide for both opaque and transparent rolls.

- Three adjustable settings for automatic unwinder: manual, roll diameter adjustment, and length adjustment.

- Automatic unwinding with EPC function (web guiding system for edge positioning control). This feature ensures alignment between the running roll and the roll prepared in the splicing unit. Sensors monitor the position of the running roll, and the automatic side guide moves to ensure alignment during splicing.

- Laser positioning for edge alignment.

- Reliable roll cutting and splicing device simultaneously cuts the mesh and applies tape, creating a tight bond of the two ends.

- DINGYU tension coupling technology ensures accurate tensioning when entering the roll.

- This non-stop unwinder monitors the diameter of operating rolls and automatically changes rolls to the preset diameter. Alternatively, the tail gripping function initiates splicing when material separates from the core, maximizing material usage and reducing waste.

| Model | HUA-350A/B |

| Weight | 1500kg |

| Voltage | 380V |

| Total Power | 4.5KW |

| Startup Power | 2.2kw |

| Dimensions (L*W*H) | 2650mm*1100mm*22400mm |

| Maximum Unwinding Diameter | 850mm |

| Maximum Unwinding Width | 320mm |

| Maximum Unwinding Speed | 100m/min;180m/min |

| Material Splicing Time | 25s |

| Material Splicing Angle | 10° |

| Edge Position Control Method | EPC |

| Material Splicing Method | Manual |

| Material Alignment Method | Laser positioning |

- Unwinding Unit

- The built-in roll handling system lifts rolls weighing up to 500 KGS with no need for auxiliary rollers, plus easy to control.

- Air-expanding shafts are available for 3-inch or 6-inch

- Conveyer belt on the unwinder facilitates easy material loading.

- Slitting Unit

- Equipped with roll cutting and splicing device that is reliable and easy-to-control, facilitating clean cutting and tight splicing.

- 10-degree angle for material feeding joint with tape on both sides (diagonal connection).

- Vacuum roller helps the worker prepare for connecting the splice tape.

- Material Rack with Floating Roller

- DINGYU tension coupling technology ensures accurate tensioning when entering the roll.

- Touch Screen Panel

- Simple procedures eliminate the need for specialized training.

- User-friendly bottoms for inflating air-expanding shafts make it unnecessary to use an air gun.

- Guiding Rail with EPC

- Automatic unwinding unit (guiding rail) with EPC ensures alignment of the material during paper splicing.

- Laser Positioning System

Laser positioning system ensures correct edge alignment of materials for accurate operator positioning.

- Length Measuring System (New)

After splicing, the system will start measuring the unwinding length of the material. When the set length is reached, the rewinder automatically cuts the web at the splice area and switches to another air-expanding shaft for continuous rewinding. This is more convenient as the splice area is also used for disposing waste material.

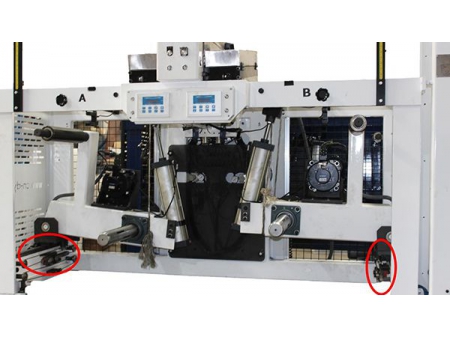

- Unwinding Completion Sensor (New)

The new splicing unit below includes a roller with a sensor. The sensing roller detects the remaining material as it leaves the inflatable shaft, and immediately sends feedback to the unwinder’s PLC for automatic splicing. This feature is mainly for protecting and ensuring the feeding end can automatically join.

- Independent Secondary Tension Control System (New)

High tension control is needed for thicker special materials, while low tension control for thin special materials. Therefore, a secondary tension control system is needed to increase/reduce tension after the material is automatically sent to the material rack. Daba Machinery add a brand-new independent secondary tension control system with an additional alignment device and an independent closed-loop constant tension controller to the non-stop unwinder, which minimizes material movement and, consequently, reduces material waste to the greatest extent possible.