Light-Stone

Innovative Architectural Facade Solutions

Manufactured using eco-friendly materials, composed of silica-based waste such as tailings, desert sand, sediment, and coal gangue, etc.

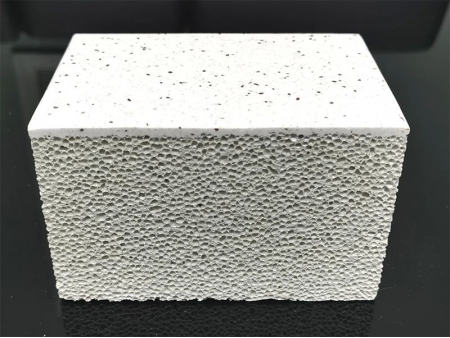

Light-stone (sustainable wall panel) is a recent advancement in wall panel technology, setting a new standard in modern construction and architectural industry. This innovative wall panel solution combines wall construction, decorative finish, and multiple functional features into a single integrated panel. Manufactured using eco-friendly materials, composed of silica-based waste such as tailings, desert sand, sediment, and coal gangue, the sustainable wall panel undergoes a high-temperature process of melting, crystallization, and foaming. The result is an advanced composite material featuring a honeycomb insulation core and a decorative surface layer, known as microcrystalline foamed tailing board. This new material sets a benchmark in green building technology, embodying the principles of sustainable and ecological construction.

The innovative wall panel offers numerous advantages, including its lightweight yet high-strength composition, fire resistance, thermal insulation, noise reduction, and integrated surface and material properties. Its durability and weather resistance make it an ideal choice for a wide range of applications, from office buildings and hospitals to schools and public venues. The wall panel is a versatile material that has transformed the landscape of building construction and material manufacturing, bringing together functionality, sustainability, and aesthetic appeal all in one comprehensive solution.

Light-stone's multifunctional properties make it an ideal solution for a wide range of applications, including architectural curtain walls, fire-resistant walls, insulation and decorative panels, and industrial anti-corrosion walls. This innovative material's versatility stems from its ability to combine structural integrity, aesthetic appeal, and performance in a single product, offering a comprehensive solution for modern construction needs.

The innovative wall panel available in standard sizes of 1200×1600×100mm and 1200×800×100mm. These panels can be easily cut or assembled into any desired size, providing flexibility for various design requirements and ensuring that the material can be tailored to meet specific project needs.

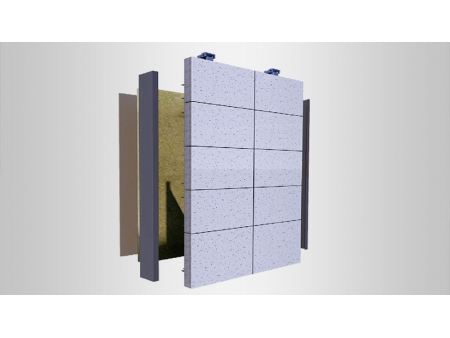

Light-Stone Used as Thermal Insulated and Decoration Integrated Panel

Light-stone panels combine a decorative surface with a foamed insulation layer through a high-temperature fusion process, eliminating issues like adhesion failures or delamination.

Light-Stone Wall Panel

Light-stone & corrosion-resistant steel are integrated to generate high-precision exterior wall construction similar to reinforced concrete, providing reliable and enduring protection.

Light-Stone Prefabricated House

Utilizing light-stone as the foundational material, these prefabricated houses are assembled from sub-millimeter precision modular units, allowing for quick and easy on-site installation. The result is a structure with the solid, enduring appearance of stone buildings, while also offering a sleek, modern aesthetic.

- NorthGlass Luoyang Company

- NorthGlass Shanghai Office Building

- A School in South Korea

- The Light-stone production line, developed by NorthGlass Light-stone Company, is a fully integrated manufacturing system that spans the entire process from raw materials → light-stone forming → light-stone processing → unitized curtain wall components. Each stage of the production process is designed and formulated by NorthGlass Light-stone to ensure the high standards of product quality and the most concise production flow.

- This advanced production line comprises four major modules: a 3-layer electrically heated and annealed roller conveyor furnace, an automated material feeding, loading and unloading center, an intelligent conveyor system, and an intelligent control system specifically for light-stone production. The current light-stone production line is based on the intricate process required for light-stone panels, which are among the most demanding products in the realm of high-temperature inorganic foaming materials due to their integrated decorative surface.

- Light-stone production technology is a cross-border integration of advanced techniques from the ceramics, glass, microcrystalline stone, inorganic foam, mechanical automation, and thermal stress sciences. This system represents a high-efficiency, energy-saving, and eco-friendly approach to automated production. Each processing stage is precisely tailored to meet the specific requirements of light-stone products, ensuring optimal quality and efficiency. The successful application of the light-stone production line in producing light-stone panels also demonstrates its broad applicability across various production needs.

- Experience the fusion of strength, style, and sustainability with light-stone, the material that's not just building the future, but redefining it.