Rotary Screw Air Compressor (Fixed Speed)

For industrial processes that require a constant air supply, a rotary screw air compressor that runs at a fixed speed will be the right tool. This page is dedicated to the MB series belt driven air compressor that features a compact, modular design. As it is constructed as a one-piece unit, the fixed speed air compressor does not use external tubing or pipe fittings, which makes construction easier. Different modules can be easily assembled or dissembled, which makes repair and maintenance easier. As it takes up very little floor space, the rotary screw air compressor delivers an efficient, reliable and exceptional performance. It is a favorite among many air operated industrial applications.

The quality rotary screw mechanism is purchased from Wolkair, and a two-notched motor is available in power capacities ranging from 11ksw to 45kw. A low noise motor is also optional to make a quiet air compressor. Please feel free to call our technical support staff with any special requirements, which our highly trained experts will use to customize your air compressor products.

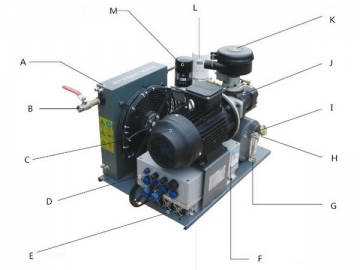

A. High efficiency air cooling system

B. WOLKAIR large capacity double-deck oil and air separator, durable and easy to change out

C. WOYO Patented inlet valve

D. WOLKAIR GCU55 integrated rotary screw mechanism

E. German top brand heavy duty air filter silencer

F. Oil level sight glass

G. High-performing intelligent monitor and electrical enclosure

H. Sound absorbing sponge

I. Air preheater

J. German top-brand belt and pulley available with protective cover

K. Unique belt tensioner for great efficiency and convenience

L. Rigid base and aesthetically appealing acoustic cladding

M. Top brand motor with class F insulation and IP54 rating

Technical Specifications

| Model Code | Operating Pressure (bar) | Volumetric Flow (m3/min) | Motor Power (kw/Hp) | Noise dB(A) | Dimensions (mm) | Outlet Pipe Diameter (G) | Weight (kg) |

| 7/8/10 | 1.6/1.5/1.4 | 11/15 | 65 | 900×680×1080 | G3/4 | 365 | |

| 7/8/10 | 2.5/2.3/2 | 15/20 | 68 | 900×680×1080 | G3/4 | 380 | |

| 7/8/10 | 3/2.9/2.7 | 18.5/25 | 68 | 1080×800×1280 | G1 | 440 | |

| 7/8/10 | 3.6/3.5/3.2 | 22/30 | 68 | 1080×800×1280 | G1 | 470 | |

| 7/8/10 | 5.2/5.0/4.5 | 30/40 | 70 | 1450×950×1400 | G1-1/4 | 820 | |

| 7/8/10 | 6.7/6.3/6 | 37/50 | 75 | 1450×950×1400 | G1-1/2 | 850 | |

| 7/8/10 | 8/7.5/6.9 | 45/60 | 75 | 1450×950×1400 | G1-1/2 | 900 |

**Note: The above models are for reference only. We can customize rotary screw air compressors to fit your needs.

Functions /Protections of Rotary Screw Air Compressor

| Remote control/On-site control | √ |

| RS-485 communication, supporting MODBUSRTU protocol | √ |

| Linkage mechanism/Computer-based centralized control | √ |

| Oil filter (time set-point entry) | √ |

| Air filter (time set-point entry) | √ |

| Oil and air separator (time set-point entry) | √ |

| Lubricating oil(time set-point entry) | √ |

| Lubricating grease (time set-point entry) | √ |

| Belt (time set-point entry) | √ |

| Motor protection (overload, phase loss, imbalance, over-voltage, under-voltage) | √ |

| Blower overload protection | √ |

| Low temperature protection | √ |

| Discharged air over-temperature protection | √ |

| Screw reverse rotation protection | √ |

| Air supply over-pressure protection | √ |

| Sensor failure protection | √ |

VI. Display, Alarm, Interlock (power failure protection)

| Items | Display | Alarm | Interlock | Note |

| Oil filter (time set-point entry) | √ | √HA | ||

| Air filter (time set-point entry) | √ | √HA | ||

| Oil and air separator (time set-point entry) | √ | √HA | ||

| Phase order protection | √ | √ | √ | |

| Discharge end temperature | √ | √HA | √ | |

| Discharge end pressure | √ | |||

| Thermocouple failure | √ | √ | √ | |

| Startup Timeout | √ | √ | √ | |

| Fan failure | √ | √ | ||

| Main unit failure | √ | √ | √ | |

| Air supply temperature | √ | |||

| Alarm Record | √ | |||

| Operating Time | √ | |||

| Integrated Control | √ |