Rotary Screw Air Compressor (Economical Type)

Welcome to Woyo, where we provide customers all over the world with standard rotary screw air compressors and customized air compressor solutions. They know that we will make every effort possible to meet each and every one of their needs. This page details the MD series rotary screw air compressor, which is ranked at the top of its class for efficiency, cost savings and customer preference. As a best seller for ten consecutive years, the MD series economy air compressor is known for its stability and its less than 1% failure rate within the warranty period. On average, we sell more than 100 units annually.

The MD 22 model rotary screw air compressor promises incredible cost savings. Assuming this belt-driven air compressor is used for 7,000 hours a year, the total cost for replacement filters, lubricating oil and other consumable parts is as low as $395 per unit.

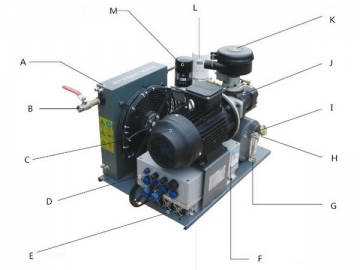

1. Rotary Screw

The GU series belt driven rotary screw is a Wolkair brand, imported from Germany. As it is designed to run at a fixed speed, this belt-driven rotary mechanism allows for easy belt adjustments. With just a couple modifications, the drive system can accommodate a built in large capacity oil and air separator to control the oil carryover at less than 3 PPM.

2. IE2/IE3 Industrial Motor

Optional Voltages: 230V, 380V, 420V, 460V, 575V, 660V

Optional Frequency: 50 Hz or 60Hz.

3. The rotary screw air compressor comes with a monitoring system that keeps the compressor's operating status in check, displaying operational information including voltages, currents, temperature, and frequency. Various protections are available, including electrical ground and short-circuit protection.

4. A patented inlet valve has been tested to provide 300,000 rounds of operations at high temperatures and humidity without failing.

Technical Specifications of MD Series Rotary Screw Air Compressor

| Model Code | Operating Pressure (bar) | Volumetric Flow Rate (m3/min) | Motor Power (kw/Hp) | Noise dB(A) | Dimensions | Diameter of Discharge Pipe G | Weight (kg) |

| 7/8/10 | 1.6/1.5/1.4 | 11/15 | 65 | 730×670×1000 | G3/4 | 200 | |

| 7/8/10 | 2.5/2.3/2 | 15/20 | 68 | 870×850×1320 | G3/4 | 350 | |

| 7/8/10 | 3/2.9/2.7 | 18.5/25 | 68 | 870×850×1320 | G1 | 370 | |

| 7/8/10 | 3.6/3.5/3.2 | 22/30 | 68 | 870×850×1320 | G1 | 405 | |

| 7/8/10 | 5.2/5.0/4.5 | 30/40 | 70 | 1130×1110×1400 | G1-1/2 | 715 | |

| 7/8/10 | 6.7/6.3/6 | 37/50 | 75 | 1130×1110×1400 | G1-1/2 | 770 |

Functions/Protections

| Remote control/On-site control | √ |

| RS-485 communication, supporting MODBUSRTU protocol | √ |

| Linkage mechanism/Computer-based centralized control | √ |

| Oil filter (time set-point entry) | √ |

| Air filter (time set-point entry) | √ |

| Oil and air separator (time set-point entry) | √ |

| Lubricating oil(time set-point entry) | √ |

| Lubricating grease (time set-point entry) | √ |

| Belt (time set-point entry) | √ |

| Motor protection (overload, phase loss, imbalance, over-voltage, under-voltage) | √ |

| Blower overload protection | √ |

| Low temperature protection | √ |

| Discharged air over-temperature protection | √ |

| Screw reverse rotation protection | √ |

| Air supply over-pressure protection | √ |

| Sensor failure protection | √ |

Display, Alarm, Interlock (power failure protection)

| Items | Display | Alarm | Interlock | Note |

| Oil filter (time set-point entry) | √ | √HA | ||

| Air filter (time set-point entry) | √ | √HA | ||

| Oil and air separator (time set-point entry) | √ | √HA | ||

| Phase order protection | √ | √ | √ | |

| Discharge end temperature | √ | √HA | √ | |

| Discharge end pressure | √ | |||

| Thermocouple failure | √ | √ | √ | |

| Startup Timeout | √ | √ | √ | |

| Fan failure | √ | √ | ||

| Main unit failure | √ | √ | √ | |

| Air supply temperature | √ | |||

| Alarm Record | √ | |||

| Operating Time | √ | |||

| Integrated Control | √ |