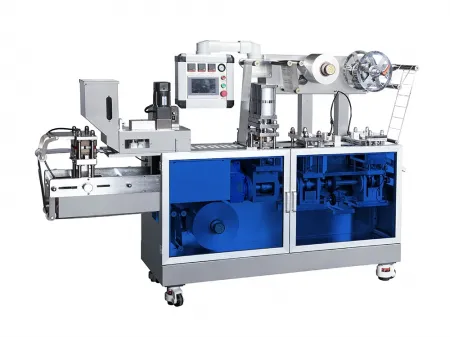

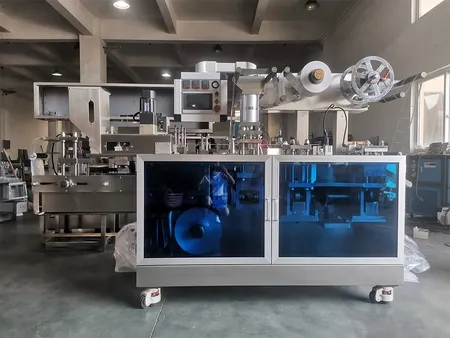

Multi-Functional Blister Packaging Machine

Request a Quote

Pharmaceutical Machinery

Packaging EquipmentDPP80

Blistering machine for Alu-Alu, Alu-PVC and Paper-PVC blister packs

- Up to 45,000 Blisters Per Minute (Alu-Alu)

- Up to 110,000 Blisters Per Minute (Alu-PVC)

This multi-functional blister packaging machine is equipped with online detection and automatic waste rejection functions, ensuring efficiency and precision in packaging. Controlled by a PLC system and operated via a user-friendly touchscreen, the blistering machine incorporates a frequency converter for smooth operation. It is widely suitable for packaging capsules, tablets, honey pills, candies, liquids (ointments), syringes, and irregularly shaped items in Alu-Alu, Alu-PVC, or paper-PVC blister packs. Its versatility makes it an excellent choice for the pharmaceutical, medical, food, cosmetics, and medical device industries.

Key features

- Equipped with advanced PLC control system with touchscreen operation. The main drive system uses parallel shafts and helical gear reducers, offering a novel design with stable performance, long service life, and low noise.

- Multiple feeders available to suit different product types

- When the machine stops, the sealing cylinder automatically disengages to prevent product damage and extend its lifespan.

Specifications

| Cutting Frequency | Alu-Alu: 6-25 cycles/min Alu-PVC: 6-50 cycles/min Paper-PVC: 6-50 cycles/min |

| Max. Production Capacity | Alu-Alu: ≤45,000 blisters/h Alu-PVC: ≤110,000 blisters/h |

| Max. Forming Area & Depth | Alu-Alu: 130×130×14 mm Alu-PVC: 130×130×26 mm |

| Stroke Length | 40-140mm (customizable) |

| Standard Plate Size (L×W) | 80×57mm (customizable) |

| Air Pressure | 0.4-0.6MPa |

| Air Supply | ≥0.2m³/min |

| Total Power | 380V/220V 50Hz 3.6kW |

| Main Motor Power | 0.75kW |

| Forming Aluminum Foil (T×W) | 0.1-0.15×150mm |

| PVC Sheet (T×W) | 0.15-0.5×150mm |

| PTP Aluminum Foil (T×W) | 0.02-0.035×150mm |

| Dialysis Paper | 50-100g×150 mm |

| Machine Dimensions (L×W×H) | 2300×560×1410 mm |

| Machine Weight | 750 kg |