Aluminum Rod Breakdown Machine with Individual Motor

Request a Quote

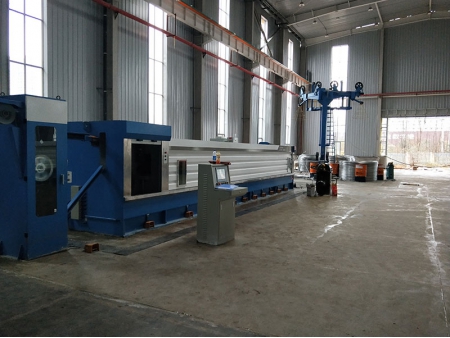

Wire drawing machine for aluminum and aluminum alloy wires

The aluminum rod breakdown machine with individual motors is used to produce aluminum wires sized ⌀1.6-4.5mm from aluminum rods of ⌀9.5mm, or wires sized ⌀2.1-4.5mm from aluminum alloy rods of ⌀9.5mm.

Features

- Used for drawing round and irregular lines from aluminum and aluminum alloy rods; coiling into spools or reels.

- The wire drawing machine can have either gear drive or individual motor drive structures. Additionally, single-head or double-head wire drawing machine structures can be selected based on cross-section specifications, production needs, and available space.

- Gear drive is suitable for 1 series and 8 series electrical aluminum rods; individual motor drive can produce 1 series, 8 series, and 6 series electrical aluminum rods, offering stable product quality, high production efficiency, and low noise.

- Each drawing ring in the individual motor wire drawing machine is driven by an independent motor. Each compression ratio can be appropriately set, facilitating mold matching and accommodating various grades of aluminum wire drawing.

- The take-up machine (optional) can use single spool, automatic spool change, vertical pay-off, or a combination of various take-up forms.

- The electrical system uses an MMI PLC control system for synchronized control of the production line, enabling online monitoring. Process parameters can be modified, stored, and read on the touch screen, ensuring simple and fast operation.

- Auxiliary equipment such as threading machines, cold welding machines, heat exchangers, and filters for drawing oil can be provided, offering comprehensive turnkey engineering services.

Specifications

| Drive mode | Model | Inlet wire rod diameter (mm) | Number of wires | Outlet wire diameter (mm) | Max. speed (m/s) | Max. drawing pass | Capstan diameter (mm) | Installed capacity (kVA) |

| Shunt drive | LWHD-450/9 | ⌀9.5 | 1 | ⌀2.5-⌀4.5 | 25 | 9 | ⌀450 | 350 |

LWHD-450/11 | ⌀9.5 | 1 | ⌀2.0-⌀4.5 | 25 | 11 | ⌀450 | 420 | |

LWHD-450/13 | ⌀9.5 | 1 | ⌀1.6-⌀4.5 | 28 | 13 | ⌀450 | 480 | |

LWHD-450/11(S) | ⌀9.5 | 2 | ⌀2.6-⌀4.5 | 25 | 11 | ⌀450 | 460 | |

LWHD-450/13(S) | ⌀9.5 | 2 | ⌀2.0-⌀4.5 | 28 | 11 | ⌀450 | 460 | |

| Inline gear drive (single motor) | LWHD-450/9 | ⌀9.5 | 1 | ⌀2.5-⌀4.5 | 22 | 9 | ⌀450 | 300 |

LWHD-450/11 | ⌀9.5 | 1 | ⌀2.0-⌀4.5 | 25 | 11 | ⌀450 | 350 | |

LWHD-450/13 | ⌀9.5 | 1 | ⌀1.6-⌀4.5 | 28 | 13 | ⌀450 | 400 | |

LWHD-450/13(2) | 2*⌀9.5 | 2 | ⌀2.0-⌀4.5 | 28 | 13 | ⌀450 | 600 | |

| Take-up options 1. 630 single bobbin take-up 2. 630 dual bobbin take-up 3. 800 single bobbin take-up 4. 800 dual bobbin take-up 5. 820 vertical pay-off 6. or custom combination | ||||||||