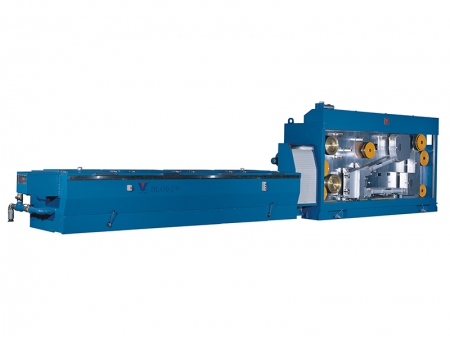

Copper Rod Breakdown Machine with Individual Motor

Request a Quote

Wire drawing machine for copper wires

The copper rod breakdown machine with individual motor is designed for drawing copper wires from ⌀8mm low-oxygen or oxygen-free copper rods to ⌀1.2-4.5mm. This machine also performs annealing during the drawing process, producing high-quality copper wires for electrical purposes.

Features

- Combines wire drawing and annealing processes, ensuring high production efficiency and stable wire properties.

- Available with gear drive or individual motor drive systems. Choose between single-head or double-head configurations based on your production needs and space constraints.

- Both gear drive and individual motor drive systems offer high production efficiency, stable product quality, and low operational noise.

- Each drawing drum is independently driven by its own motor, allowing precise control of compression ratios for better mold matching and adaptability to different copper grades.

- Optional take-up systems include single spool, automatic spool change, and vertical pay-off configurations, allowing flexibility in production.

- Utilizes an MMI PLC control system for synchronized control of the entire production line. Real-time monitoring and easy adjustment of process parameters via the touch screen ensure efficient and user-friendly operation.

- Offers a range of auxiliary equipment, including threading machines, cold welding machines (or resistance butt welding machines), heat exchangers, and oil filtration systems, providing a complete turnkey solution for seamless operation.

Specifications

| Drive mode | Model | Inlet wire rod diameter (mm) | Number of wires | Outlet wire diameter (mm) | Max. speed (m/s) | Max. drawing pass | Capstan diameter (mm) | Installed capacity (kVA) |

| Shunt drive | LWHD-450/9 | ⌀8 | 1 | ⌀2.1-4.0 | 25 | 9 | ⌀450 | 580 |

LWHD-450/11 | ⌀8 | 1 | ⌀1.7-4.0 | 28 | 11 | ⌀450 | 630 | |

LWHD-450/13 | ⌀8 | 1 | ⌀1.2-⌀4.0 | 30 | 13 | ⌀450 | 680 | |

LWHD-450/9(2) | 2×⌀8 | 2 | 2×⌀2.0-3.5 | 25 | 9 | ⌀450 | 1000 | |

LWHD-450/11(2) | 2×⌀8 | 2 | 2×⌀1.6-3.5 | 28 | 11 | ⌀450 | 1100 | |

LWHD-450/13(2) | 2×⌀8 | 2 | 2×⌀1.3-3.5 | 28 | 13 | ⌀450 | 1200 | |

| Inline gear drive (single motor) | LHD-450/9 | ⌀8 | 1 | ⌀2.1-4.2 | 22 | 9 | ⌀450 | 500 |

LHD-450/11 | ⌀8 | 1 | ⌀1.7-4.2 | 23 | 11 | ⌀450 | 580 | |

LHD-450/13 | ⌀8 | 1 | ⌀1.2-⌀4.2 | 25 | 13 | ⌀450 | 630 | |

LWHD-450/9(2) | 2×⌀8 | 2 | 2×⌀2.0-3.5 | 21 | 9 | ⌀450 | 900 | |

LWHD-450/11(2) | 2×⌀8 | 2 | 2×⌀1.6-3.5 | 23 | 11 | ⌀450 | 1000 | |

LWHD-450/13(2) | 2×⌀8 | 2 | 2×⌀1.3-3.5 | 25 | 13 | ⌀450 | 1100 | |

| Take-up options 1. 630 single bobbin take-up 2. 630 dual bobbin take-up 3. 800 single bobbin take-up 4. 800 dual bobbin take-up 5. 820 vertical pay-off 6. or custom combination | ||||||||