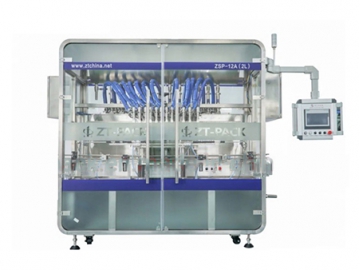

Liquid Filler

1.

Applications

As a kind of semiautomatic piston liquid filling machine, the liquid filler is suitable for filling various low viscosity liquid products like fruit juice, liquid soap, liquid chemical products, and others.

Main Features

1. The liquid filler is compliant with GMP standard, and all parts that touch products are made of stainless steel.

2. The filler provides high precision, with filling volume and speed adjustable.

3. Filling head of the liquid filler makes use of anti-drip and anti-drawing device.

4. Combined with packaging machine and other packaging related equipment.

Main Specifications

| Machine name | Liquid Filler |

| Model | RZYT-500 |

| Working mode | Piston type |

| Weighing range | 10-500ml(can be customized to 3000ml) |

| Weight accuracy | ±1% |

| Speed | 0-50times/min |

| Hopper volume | 70L |

| Voltage | 380V 3-Phases 50/60HZ |

2 .

Applications

The thick liquid filler is ideal for tomato sauce, peanut butter, jam, bean paste, detergent and other paste products. The sauce filler is a kind of semiautomatic piston liquid filling machine, which is used for filling various high viscosity liquid products.

Main Features of Sauce Filler

1. The liquid filler is compliant with GMP standard, and all parts that touch products are made of stainless steel.

2. The sauce filler provides high precision, with filling volume and speed adjustable.

3. Filling head of the sauce filler makes use of anti-drip and anti-drawing device.

4. Combined with packaging machine and other packaging related equipment.

Main Specifications

| Machine name | Liquid Filler |

| Model | RZYT-500 |

| Working mode | Piston type |

| Weighing range | 10-500ml(can be customized to 3000ml) |

| Weight accuracy | ±1% |

| Speed | 0-50times/min |

| Hopper volume | 70L |

| Voltage | 380V 3-Phases 50/60HZ |

Liquid filler falls into three categories, namely, atmospherical pressure filling machine, pressure filling machine and vacuum filling machine.

For the atmospherical pressure filling machine, there are two types, i.e. timed filling and metered volume filling. The atmospherical pressure filling machine suits low viscosity non-carbonated liquid like milk and wine, etc. While the pressure filling machine can be used for filling beer, aerated water, and champagne, etc. The vacuum filling machine provides simple structure and high efficiency. A variety of materials with varied level of viscosity are applicable, such as oils, syrup, cider, and others.

Work Flow

The liquid filler works in a process like this. The cases filled with empty bottles are stacked onto the trays, which are transported to an unpacker by a conveying belt. The empty bottles are taken out for cleaning and sterilization, when the cases are tidied clean for packing the bottles filled with liquids. Before filling and sealing, the bottles are inspected to meet related cleanliness standards. Finally, the bottles are conveyed to a labeler for labeling.

RezPack is a professional liquid filler manufacturer, located in China. Since it was founded, RezPack strives to provide the highest quality packaging machinery for customers all over the globe. Quality management in line with ISO9001 international standards helps RezPack achieve this goal. At present, RezPack pillow type packaging machine, vertical packaging machine, measuring equipment, conveyor equipment, etc, are CE certified and increasingly used by international customers. If you are in search of high quality low priced packaging machine, the staff at RezPack welcomes you to try its products and looks forward to hearing from you.