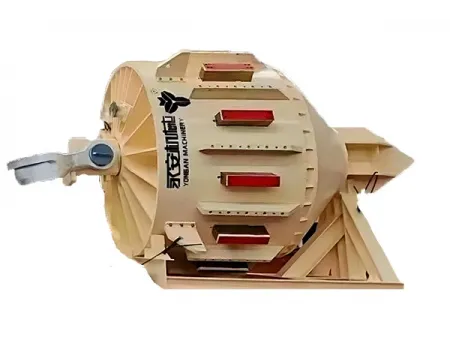

Two Stage Cementing Tool

Two Stage Cementing Tool

The XYZseries two stage cementing tool comes with inner-closetype design. As soon as the closing sleeve goes down, the circulation port isshut.

Features

1. The opening pressure for the two stage cementingtool is adjustable, and the operation is not subject to the holeangle.

2. Circulation port can be opened, closedand operated, without causing fluid compression in the cavity.

3. The inner diameter of upper/lower subis the same as that of casing, but smaller than that of the closing sleeve. The chances of damages to the closing sleevecan thus be minimized.

4. All the components are made of drillablerubber or aluminum materials. The two stage cementing tool comes with rotationlocking system for easy drilling.

XTZ Series Two Stage Cementing Tool

Parameters

| Specifications (mm) | Φ139.7 | Φ177.8 | Φ244.5 |

| Max. outside diameter (mm) | 170 | 208 | 283 |

| Drift diameter (mm) | 122 | 155 | 220 |

| Total length (mm) | 1082 | 1182 | 1222 |

| Rated load (t) | 140 | 170 | 210 |

| Sealing capacity (Mpa) | 25 | 25 | 25 |

| Opening pressure (MPa) | 7 | 7 | 7 |

| Opening force (KN) | 85 | 136 | 278 |

| Closing pressure (MPa) | 5 | 5 | 5 |

| Closing force (KN) | 60 | 97 | 199 |

| Inner diameter of the lower sliding sleeve (mm) | 85 | 115 | 176 |

| Inner diameter of the upper sliding sleeve (mm) | 95 | 125 | 197 |

Accessories of Two Stage Cementing Tool

Theaccessories of DSG and SJG series two stage cementing tool include first stage plug,free-fall opening plug, closing plug, shut-off baffle and pump-down openingplug. These components, made of rubber and aluminum, are readily drillable.

1.The shut-off baffle is fixed in the casing collar above the float collar.

2. Thefirst-stage plug is used to isolate grout and drilling fluid. At the end ofdisplacement,

3. Thestreamlined free-fall opening plug, filled with lead, can quickly free-fall tothe upper sliding sleeve. After applying certain pressure to the casing, theplug can open the circulation ports.

4.The closing plug serves to separate the second-stage cement and drilling fluid.Then it comes to the upper sliding sleeve to form a seal in the stage cementer.As you continue to pressurize, the closing sleeve goes down and the circulationports are closed.

5.The pump-down opening plug suits use for continuous cementing operation and in deviatedwells. It can open the circulation ports directly and quickly.

Parameters

| Model | DDS | ZDS | |||||

| Specifications (mm) | Φ139.7 | Φ177.8 | Φ244.5 | Φ339.7 | Φ73 | Φ88.9 | Φ127 |

| Total length (mm) | 1400 | 1450 | 1700 | 1700 | 910 | 1012 | 1125 |

| Manifold | Φ50.8 Union | ||||||

| Inner diameter of plug container (mm) | 125 | 160 | 225 | 320 | 52 | 72 | 100 |

| Length of plug container (mm) | 450 | 450 | 550 | 550 | 290 | 340 | 405 |

| Max. operation pressure (MPa) | 35 | 35 | 35 | 20 | 35 | 35 | 35 |

Thanks for visitingour website! Rundong is an experienced Chinese twostage cementing tool manufacturer and supplier, established in 1970. We providea wide variety of mud pump, valve, water drill rig, and more. Our location in