Horizontal Vibration Vacuum Dryer

Request a Quote

ZDG Series Horizontal Vibration Vacuum Dryer

Their innovative design and versatility make these horizontal vibration vacuum dryers an excellent choice for industries prioritizing quality and efficiency. By using external mechanical vibrations, the drying system fluidizes materials within a vacuum chamber, allowing for smooth, spiral movement while suspended. This process ensures uniform drying by heating the materials through a jacketed chamber, evaporating water and solvents which are then efficiently removed. Recently, a new three-in-one model was developed, offering exceptional performance for the drying of new energy materials.

Applications

- Ideal for drying advanced materials used in battery production

- Efficiently dries raw ingredients and specialized medications

- Supports the processing of organic and inorganic chemicals, including fertilizers and petrochemicals

- Nanoparticles & Powders: Highly effective for drying nano-scale particles, slurries, and filter cakes

Specifications

| Model | Heat exchange area (m²) | Motor (kW) | Weight (kg) |

| | 0.81 | 1.1 | 500 |

| | 2.45 | 1.5 | 1100 |

| | 3.83 | 2.4 | 1400 |

| | 4.79 | 3.2 | 1600 |

| | 5.80 | 3.2 | 2400 |

| | 6.92 | 5.5 | 2700 |

| | 8.80 | 5.5 | 3100 |

| | 11.84 | 7.5 | 4200 |

| | 13.50 | 7.5 | 4500 |

Features

- The fully enclosed jacketed design ensures rapid heating with minimal heat loss, achieving a thermal efficiency of over 70%

- The entire drying process meets GMP and FDA standards, ensuring vacuum feeding, vibration discharge, and zero contamination during operation

- The system allows for interchangeable water inlets and outlets, ensuring rapid cooling for heat-sensitive materials and maintaining product quality

- Capable of sterile processing with in-chamber steam sterilization, offering safety, reliability, and ease of use

- Powder materials vibrate vertically and move uniformly along the chamber walls, creating a floating effect that significantly reduces wear on the chamber and is especially beneficial for abrasive materials

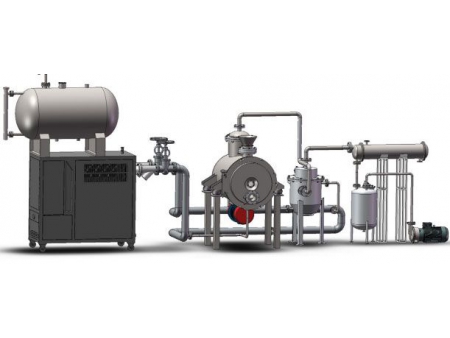

Process Flow Diagram

Get in Touch

Need help finding the right product? Please fill the form and we will be in touch with you as soon as possible.