KS311 Hydraulic Longhole Drilling Rig

KS311 underground drilling rig operated for tunnel construction in 2020

KS311 Hydraulic Longhole Drilling Rig for Mining in Kazakhstan

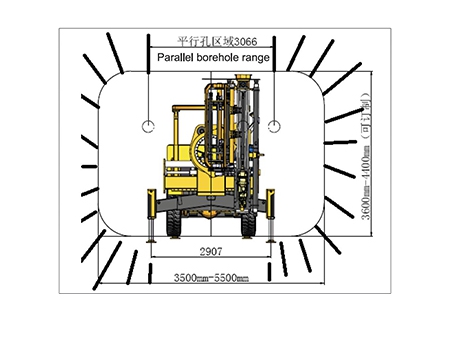

The KS311 Hydraulic long-hole drilling rig is mainly used for blast drilling operations in medium-scale production drilling in underground mining application. Both the applicable height and width of tunnels fall in the range of 3.5m-5m. The support for the drill boom is capable of 360-degree rotation. In combination with a swing boom and translational guide rail, it is capable of 360-degreee drilling and parallel drilling within three meters, thus meeting the requirements of various mine drillings.

Application and feature

1. The automatic rod-changing system has a storing capacity of 27 drill rods and the drilling depth can reach as far as 42 meters.

2. The front and rear of the advancing beam are fitted with hydraulic supporting cylinders for smooth drilling. It is fitted with the hydraulic guiding cylinders and thus ensures drilling straightness.

3. The trolley-type workbench with a good sight is adopted; and the wireless remote controller can serve as an option.

4. The articulated mining chassis of closed hydraulic drive is suitable for small and medium-sized tunnels.

5. The stepped piston is used for the high-frequency impacting rock drill and this can improve the transmission efficiency of impact wave and drilling speed and reduce the consumption of drilling tools.

- Diagram of working range

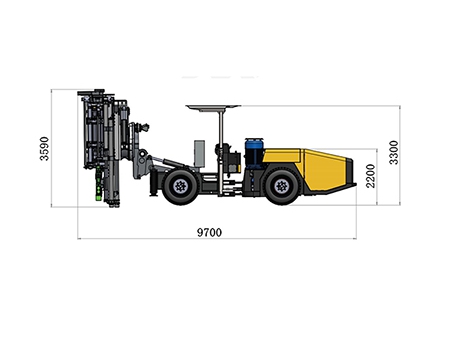

- Dimensions during operation

- Dimensions during travelling

1、Dimensions and weight

| Width | 2300mm | ||

| Height | 3300 mm | ||

| Weight | 16000 kg /Appr. 16000㎏ | ||

| Tramming speed on flat ground | 10km/h | ||

| Maximum climbing capacity | 25% (14°) |

| Lifting safety roof | Meet the requirements of FOPS and ROPS |

| Impact power | 24kW | |||||

| Impact flow | 138L/min | |||||

| Impact pressure | 200bar | |||||

| Maximum rotary pressure | 210bar | |||||

| Impact Frequency | 48-57 Hz | |||||

| Torque | 955Nm | |||||

| Shank thread | T38、T45 | |||||

| Hole diameter | 64-76 | 89-102 | ||||

| Thread of drill rod | T38 | T45 | ||||

| Drilling depth | 42m | 42m | ||||

| Pitch angle of advancing beam | 20°, 65 /Front: 20°, back: 65° | |||||

| Ring angle | 360° | |||||

| Rang of Parallel holes | 1500mm /1500mm each side | |||||

| Length of drill rod | 1525mm | 1830mm | ||||

| Length of advancing beam | 3500mm | 3800mm | ||||

| Feed extension | 1200mm | 1200mm | ||||

| Impact /Feed/ Positioning | Axial variable displacement piston pump | |||||

| Rotation | Gear pump | |||||

| Filter Accuracy | 10μ | |||||

| Hydraulic oil tank | 240 L | |||||

| Hydraulic cooler | water cooler | |||||

| Working voltage | 380V | |||||

| Frequency | 50HZ | |||||

| Starting method | Star-triangle | |||||

| Cable reel | 1×K440 | |||||

| Length of reel cabling | 80m | |||||

| Outer diameter of cable | Φ32mm | |||||

| Cable specifications | 3×50 3G10 | |||||

| Air compressor | 1×JN4 | ||||

| Capacity of air compressor | 0.5 m³/min | ||||

| Pressure | 5-7bar | ||||

| Device of shank lubrication | Electronic pulse lubrication pump | ||||

| Air consumption of lubrication | 0.3 m 3/min | ||||

| Oil Consumption of lubrication | 180-250 g/h | ||||

| Water pump | 1×CR10 | ||||

| Power | 5.5kW | ||||

| Capacity of water pump | 8m3/h | ||||

| Diesel engine | Cummins QSB3.9-C125/93kW /2200rpm | |||

| Exhaust purification | Exhaust catalyst | |||

| Drive system | Closed travelling system of four-wheel drive | |||

| Swing angle | Swing of rear axle:±10° | |||

| Tires | 12.00-20 | |||

| Steering mechanism | Articulated steering: ±40° | |||

| Travelling braking | Double-circuit hydraulic brake | |||

| Parking braking | Wet multidisc brake of reducer | |||

| Fuel tank | 90L | |||