LPG Fired Powder Coating Oven

Request a Quote

- COLO-0813 LPG powder coating oven is efficient and reliable, which makes temperature rise quickly with less fuel.

- Superb performance ensures constant temperature and provides an optimum curing for a durable finish.

- With operating dimensions of 0.8x1.5x3m, it suits for batch production of small sized parts or long shaped work parts.

- Built with premium components to ensure the reliable quality and maximize the service life.

- The powder coating oven can be designed with natural gas heating, LPG heating or diesel heating.

| Model | COLO-0813 |

| Operating dimensions | 800 width x 1500 height x 3000 depth mm |

| Overall dimensions | 1200 width x 1400 height x 3500 depth mm |

| Power supply | LPG / natural gas / diesel |

| Voltage | 220V/380V |

| Frequency | 50-60 Hz |

| Warm-up time | 15-30min (180°C) |

| Temperature stability | <± 3-5°C |

| Temperature Max | 250°C |

| Ventilation performance | 1131-2565m3/h |

| Motor power | 3 kW |

| Burner | Italy Riello, 100,000cal |

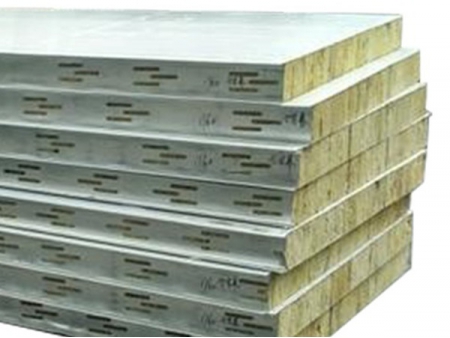

Oven Materials

The wall panel features a sandwich structure which is composed of three layers including 100mm rock wool board as the core material, galvanized wall as the lower sheet and color-steel as the upper sheet to form an optimum insulation structure.

Burner

Italy imported Riello burner takes full utilization of fuels to heat up air. The hot air is transferred by a heat exchanger, and then supplied to the heating room, realizing quick rise to a required temperature inside oven chamber.

Circulation Fan

Circulation fan cycles hot air through the entire chamber, ensuring uniform temperature to obtain consistent and even powder coating finish.

PLC Controller

The heating unit and fan system are controlled via the PLC controller. Control panel allows the operator to read a digital display of temperature and adjust the parameters accordingly.

Transport System

- Supplying with two trolleys ensures high purity painted elements.

- Inner trolley moves across the hall that does not contaminate the inside of oven, while outer trolley loads the inner trolley for outside transportation.

- Custom design is available to get an optimal use of the entire space of oven.

Related Names

Powder Coating Room | Powder Coating Booth | Powder Coating Painting Booth | Powder Curing Oven | Powder Coating Oven