Design Capacity

XIAOYA’s technical center includes a tooling and technological equipment research center with over 20 tooling senior R&D engineers and more than 50 experienced and skilled engineering technical personnel.

The tooling research center is responsible for the R&D of dies, gauges, fixtures and welding stations for a variety of steel discs and rims, as well as the design of different stamping dies. The technological equipment research center is engaged in wheel rim production line, production techniques, and standard manufacturing production.

XIAOYA uses CAD/CAE/CAM integral design and analysis software, reverse engineering and three-dimension design, achieving a closed process for virtual design, manufacturing techniques and engineering installations. This effectively ensures product quality and shortens the manufacturing cycle.

Stamping die DL drawing design and CAE analysis techniqueXIAOYA has been dedicated to the process design and analysis of stamping products made from high strength plate and thick plates. Through analysis software from Autoform and ThinkDesign, combined with our manufacturing experience, a full springback compensation solution for auto parts made from high strength plates has been successfully carried out. Based on a CAE simulation analysis, we have optimized the die design and process layout to provide a powerful technical support for the design and production of stamping dies.

- Junction plate of canopy

- DL-Draw

- DL-Trim, Cam Trim, Pierce

- DL-Flange,Pierce

- DL-Separate, Pierce, Cam Restrike

- Simulation results of CAE analysis

- Material reducing rate analysis results

- Wrinkling analysis results

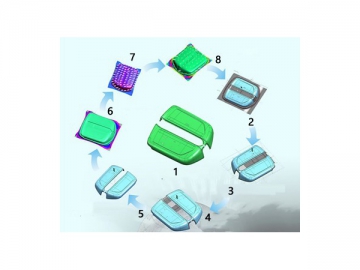

XIAOYA designs and manufactures tooling for a variety of steel wheel spokes and rims according to customer drawings, techniques, and equipment. We also support reverse engineering based on your product sample and customize process routines and die structures according to customer production equipment and quality requirements.

- Reverse Design

- CAE Analysis and Optimization

- Technics Design

- Mold Design

- Mold Production

- Trial Production

- Quality Test

- Project Delivery

XIAOYA uses a standard design for added machining and maintenance convenience for commonly used springs, guide pillars, guide sleeves, locating pines, fastening bolts and other tooling general components. We have also built an enterprise standardization design system and standardized parts database for non-generic components in order to improve our standard design level.