Fully Automatic Wet Wipes Lid Applicator Machine

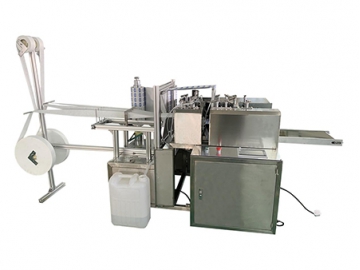

DCL-28D Lid Applicator (70-90 lids/min)

Wet wipe packaging machine integrating lid feeding, labeling and application

- Production Speed 70-90 lids per minute

- Design Speed 100 lids per minute

This fully automatic wet wipes lid applicator is designed for precision and speed, featuring Delta vision control system and four lid feeding slots for smooth, high-speed operation at 70-80 packs wet wipes lid placement per minute. It automatically feeds semi-finished wet wipes packages, captures images before lid placement, and applies the lid with perfect accuracy.

The guide rails ensure the product is perfectly aligned, while the integrated systems for lid feeding, labeling, and application handle the gluing and lid placement effortlessly. Equipped with hot melt glue boxes, glue coating units, servo-controlled lid pickers, and servo-controlled lid applicators, this lad applicator machine guarantees fast, efficient, and high-quality lid application with minimal waste.

With servo control across all mechanisms, the it ensures consistent and precise results, making it the ideal solution for wet wipe packaging.

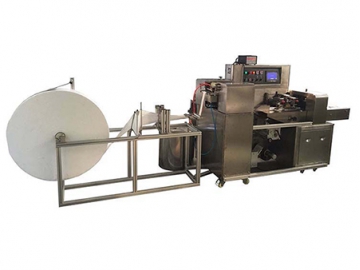

Semi-Finished Product Conveying → Camera Detection → Lid Feeding → Lid Labeling → Lid Gluing → Lid Application → Finished Product

| Production speed | 70-90 lids/min | Deviation of lid position | ±2mm |

| Design speed | 100 lids/min | Material | Plastic lid, label and hotmelt adhesive |

| Lid application height | 40-100mm | Voltage | 380V 50Hz three phase |

| Lid size | Length: 50-120mm Width: 50-80mm Height: 3-10mm | Power | Approx. 12kW |

| Product size | Length: 50-300mm Width: 50-200mm Height: 20-100mm | Machine dimensions (L×W×H) | 2995×1311×1980mm |

| Label roll size | Width: ≤80mm Diameter: ≤350mm |

- Conveyor system: Transports semi-finished products → product imaging → lid application → finished product output

- Guide rails: Keeps the product aligned in the center for precise placement

- Camera detection: Consists of camera, lens, light source, and vision controller, used to capture product position and compare it with system settings for alignment

- Lid placement: 4 sets of lid feeders, 2 active sets and 2 standby sets, with automatic rotation in the absence of lids and an alarm system to notify missing lids

- Lid labeling: Applies the lid label; stops automatically if no lid is detected

- Lid delivery: A belt with a stopper block feeds lids to the designated position; controlled by variable frequency drive

- Lid gluing: Metering pump delivers precise amounts of glue to the glue coating unit, with pump timing adjustable via the touchscreen

- Glue coating: Composed of a glue box, coating mold, and cylinder, with the cylinder controlling mold movement, raising for gluing and lowering for unloading

- Coating mold: Custom-designed based on lid coating pattern for efficient application, ensuring clean, precise gluing with no overflow or clogging 1

- Lid pickup robotic arm: Picks up the lid → applies glue → delivers the lid to the coating mold, with servo-controlled alignment for precision 1

- Lid placement robotic arm: Picks up the lid → places it accurately onto the wet wipes pack, with servo-controlled alignment to ensure perfect lid placement