Gold Gravity Separation Line

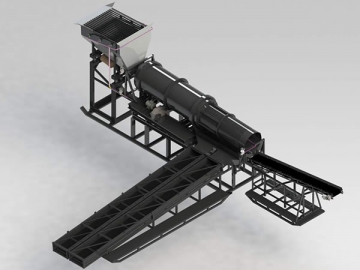

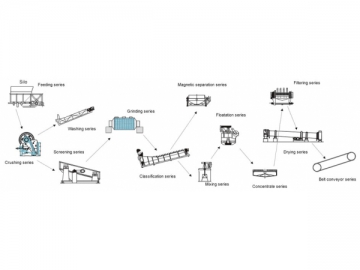

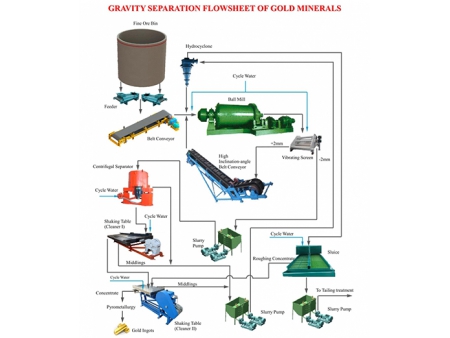

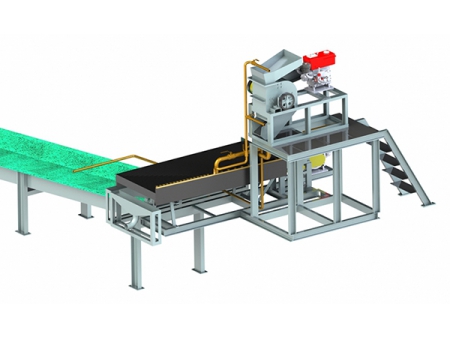

In our gold gravity separation line, equipment adopted mainly consists of pulsating sluice box, shaker, washbox and centrifugal machine. Both pulsating sluice box and centrifugal machine are suitable for mechanical cleaning of rough concentrate. They feature large capacity and high recovery rate. Moreover, they require smaller installation space. Hence, fixed chute in gravity separation line will be replaced by them gradually without any doubt.

Trommel screen is also utilized for further size reduction and segregation. We are capable of optimizing the design of the screen based on research of ore characteristics. We manage to make better use of mechanical energy and hydraulic power, increase residence time of particles in the screen and make the sieving area account for more than 25 percent of the total surface area. Furthermore, the screen is fitted with hold-material rings, spiral crushing teeth, and longitudinal lifting blades in the interior. As a result, the efficiency of crushing and screening significantly boosted. The screen also ensures high efficiency of gold concentration if working with a centrifugal machine.

With a compact device layout, our process also involves dehydration and desliming of raw ore to separate heavy gold-bearing ore. The final product will be produced directly in the dressing plant on shore. Driven by the height difference between the equipment and the environment, ore pulp will automatically flow back to where it comes from or the pool created on the site. This simplified gold concentration process ensure higher recovery and less gold loss, so that it will completely take the place of the process where only fixed chute and a washbox are utilized in the future.