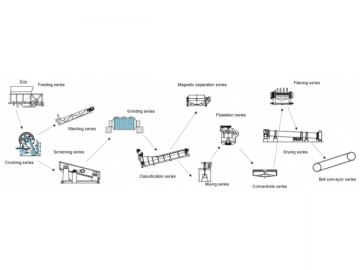

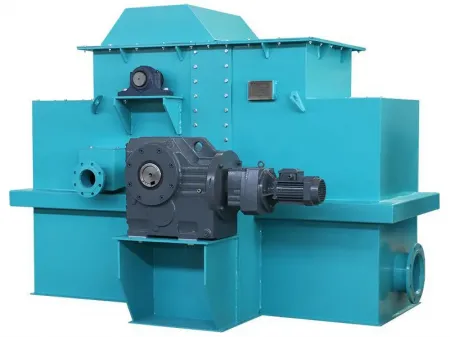

Fluorite Separation Line

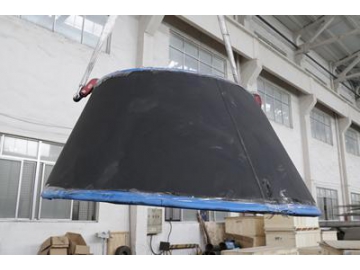

Both gravity concentration and flotation are suitable for beneficiation of fluorite. In a gravity concentration process, only washbox can be used because only washbox is capable of beneficiating coarse fluorite. Flotation of fluorite requires similar devices used in separation of other minerals, which includes crusher, ball mill and flotation machine.

Our fluorite separation line can be applied for concentration of refractory fluorite which is characterized by high content of mud in the crude ore, tight paragenesis between impure minerals and fluorite and fine-grained valuable minerals.

Application Case

In a fluorite mine in Hebei, the fluorite featured low grade, high oxidation degree, small dissemination size, and low hardness. Their original production process consisted of one roughing, regrinding of coarse concentrate and six separations. The concentrate grade was 88 percent and the recovery was 75.56 percent. These bad results severely degraded their economic benefit.

Later, they reached to us for better concentration performance and higher economic effectiveness. Based on many times of fluorite processing experiments, we were able to make some improvements with the flotation process and optimize the inhibitors. The results strongly suggested the effectiveness of our new process. Both concentrate grade and recovery were enhanced greatly. It was estimated that their annual income would be increased by 3.2 million yuan, which contributed to extra profit about 1.5 million yuan.

Indexes of finished product before and after improvement are given in the table below.

| Before and A fter I mproveme nt s | Process | Fluorite Concentrate Grade /% | Fluorite Concentrate Recovery /% |

| Before | one roughing , re grinding of coarse concentrate and six separations | 88.52 | 75.56 |

| After | scavengin g bubbles enter rough concentrate, improve reagents, add flotation cell s | 93.55 | 88.95 |