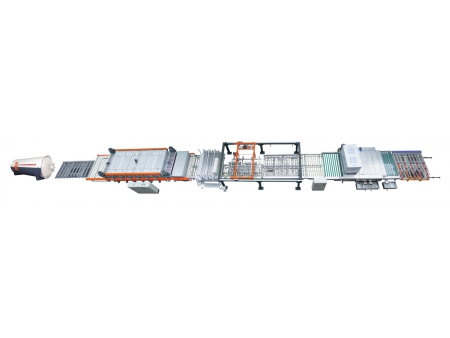

Fully Automatic Honeycomb Cardboard Production Line

The fully automatic honeycomb cardboard production line has a low process loss, and will give the products a honeycomb grain up to 99%, making it a high tech device. Its design is a technological breakthrough that allows it to work in a more efficient manner, makes the most use out of the material, and the costs for operation are significantly lower. Operated by just 4 or 5 people, the machine can produce more than 10,000 square meters of paperboard with no intermediate links, full control, and a reduction in manual labor, making it an automated production process.

Equipment Features

1.The honeycomb cardboard production line is highly automated and features a low level of technical loss. It processes up to 99% of the honeycomb paperboard.

2.The line is controlled by a computer touch screen that is easy to operate. This machine is a leader in producing honeycomb paperboard from paper on the domestic market.

3.The computer controlled line uses advanced coating technology that is used by leaders in the carton manufacturing industry all over the world. It combines the use of pneumatic and photoelectric machinery into one machine, and features a stable performance.

4.Its technical design makes the line more efficient, and gives it a lower labor cost. 4-5 employees can operate this machine to produce up to 10,000 square meters of paperboard.

5.It is dust free, odor free and pollution free, making it environmentally friendly.

6.As it is completely computer controlled, there is no intermediate link, saving labor costs and making it a fully automatic production line.

Technical Process

Feeding multi rolls of paper at the same time--Glue coating--Laminating and drying--Transverse cutting --Collecting automatically-- Stretching-- Paper core drying--Paper core glue-coating -- Or surface paper glue-coating --Feeding the surface paper -- Laminating the surface paper --Laminating and drying the paperboard -- Cooling --Cutting--Collecting

| Machine Model | WB-1800 |

| Max. core paper width | 2300mm |

| Max. surface paper width | 1800mm |

| End-product paperboard thickness | 10-80mm |

| End-product paperboard length | 800-3000mm |

| Side length of cell | 3.5-16mm |

| Production speed | 6-20m/min |

| Transverse cutting knife speed | 300times/min |

| Heating method | Steam heating, hot air cycling |

| Equipment power | 82KW |

| Overall dimensions | 77570x4800x2850mm |

| Equipment weight | 72T |

**NOTE: Data is subject to change without notice

Core Paper Unwinding Unit

1.Method: hydraulic, axle free shelf paper feeding

2.Available unwinding diameter: Φ1400mm.

3.Core inner diameter: Φ76mm.

4.Loading method: hydraulic swing clamp.

5.Tension control: controlled by pneumatic brake plate, tension control is stable, easy to operate.

6.Machine frame: integral welding structure, stable hydromantic system.

Core Paper Glue Coating Unit

1.Coating method: teeth-roller transfer coating saves glue and allows the glue content to be homogenous.

2.Double roller structure: The double rollers can produce 2 different sizes of honeycombs without changing the tooth roller.

3.Glue roller: Processed using a CNC lathe, it is ground and coated with a hard chromium, ensuring the accuracy of the pitches between the glue line.

4.The measuring roller can be adjusted from both sides. It is easy to operate and measurements are accurate.

5.Glue feeding: The glue is fed via a pneumatic diaphragm pump. The stainless glue bucket can be lifted pneumatically.

6.Pneumatic swing arm: It controls the separating of the paper from the glue roller when the machine stops, avoiding it from sticking.

7.Machine frame: single-casting structure, ensures the line will run in a stable manner.

Transverse Cutting Unit

1.Feeding: The servo feeding system’s accuracy is ±0.08mm.

2.Knife frame: Uses a high strength ductile iron with a prolonged aging treatment.

3.The knife is made of a strong alloy material, and its blade is sharp, which makes neat cuts.

4.Collection: The baffle adjusting uses a precision worm gear reducer that can be easily adjusted. It is easy to operate and can change product specifications without stopping production.

5.Feeding roller: The dynamic balance treatment ensures the stable performance under high speed operation.

6.Power: Driven by a variable frequency motor and synchronous belt, the power is stable and emits very little noise. It is easy to operate, and the knife stops at the highest position.

7.Machine frame: Single casting structure ensures the machine runs at a high speed.

Multifunctional Glue Coating Unit

1.Coating function: The surface paper coating and core paper coating can be done separately or together. It can coat 4 layers of surface paper simultaneously.

2.The adjustment of the measuring roller can be carried out from both sides, and the measuring is accurate.

3.Coting on the paper core: The unitary lifting structure makes it easy to operate the paper core with different specifications.

4.Pneumatic swing arm: It controls the separating of the paper from the glue roller when the machine stops, and prevents it from sticking together.

5.Glue feeding: The glue will be fed using a pneumatic diaphragm pump. The stainless glue bucket is lifted pneumatically.

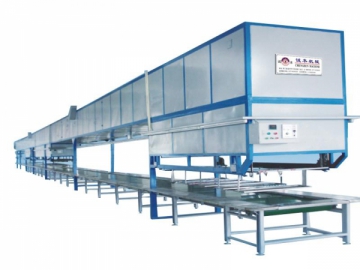

Main Laminating and Drying Unit

1.Oven structure: U-steel and steel plate welding structure, the thickness of the insulating layer is 70mm.

2.Heating method: hot air cycling improves the heating efficiency.

3.Lamination method: lamination is done by an up and down conveyor and pressed using a floating pressing roller. The paper is fed through easily with no bubbles or deboning.

4.Temperature control: The two phases of temperature control are done separately.

Round Knife Cutting Unit

1.Machine frame: The machine frame is entirely processed in a U-steel and steel plate welding structure.

2.Guide rail: uses a linear guide way, which is flexible and highly accurate.

3.Knife: The knife has a special design that makes the blade sharp and has a long service life.

4.The rod less cylinder moves transversely to cut the board with an adjustable speed and a low noise.

5.A set-length cutting system uses PLC and text control, with the accuracy at ±1mm.