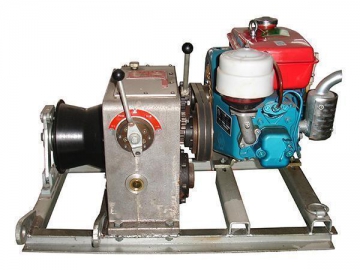

Diesel Powered Concrete Pump

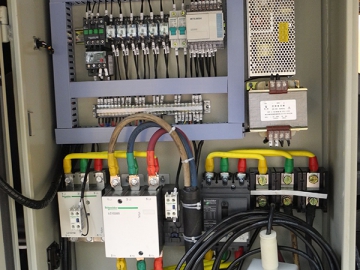

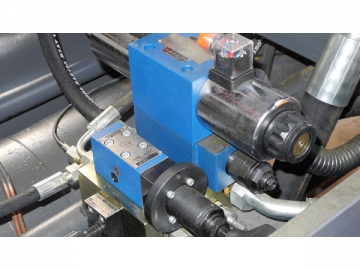

Diesel powered concrete pump features streamline appearance, reasonable layout and compacting structure. The rigidity of it hood is significantly improved. The oil pump and group valves adopted all come from international well known brands such as German Rexroth, Japanese Kawasaki and Guizhou Liyuan to ensure high reliability of the tailored-mounted pump. To obtain reliable performance and robust power, the diesel engine is purchased from Volvo, Deutz or Weichai-Deutz. All electric components in the electric control system are electric devices imported with original packaging from Japan Omron, Mitsubishi and German Siemens.

S tube is made through integral precision casting of high alloy steel. With three-dimensional optimization design, the arch hopper features large volume and is able to eliminate accumulation of materials. The main cylinder is designed with large diameter and long stroke to ensure longer delivery distance. During design of key stressed components such as the hopper and the S valve, FEM calculation of stress state, structural stiffness and stress concentration of these components are conducted using SEAS calculation program. In this way, both the hopper and the S valve can be guaranteed with high structural stiffness and great manufacturability, thus avoiding hopper deformation and S valve breakage during high-rise concrete pumping.

The diesel powered concrete pump also features easy maintenance. Hence, there is no need to dismantle the mixer base when changing the S tube, which comes with a long or short chrome plated liner. Hydraulic reversing technique is applied for design of pumping mode. Direction of movement is adjusted by changing hydraulic signals of master cylinder and slave cylinder. The concrete pump also has a high-low pressure switch-over function. Specifically, operators are enabled to use the switch valve to adjust displacement and pressure of the concrete based on specific construction requirements, and achieve energy conservation.

Other Images| Model | |||

| Main Oil Pump Discharging Capacity (ml/r) | 112×2 | 200 | 140 × 2 |

| Diesel Engine Power (KW) | 132 | 174 | 273 |

| Diesel Engine Speed | 1500 | 1800 | 2200 |

| Master Cylinder Diameter/Stroke (mm) | Φ125/1650 | Φ140/1650 | Φ150/1800 |

| Pumping Distance Horizontal/Vertical (m) | 800/180 | 1000/200 | 1500/250 |

| Concrete Cylinder Diameter/Stroke (mm) | Φ200/1650 | Φ200/1650 | Φ200/1800 |

| Main Oil Pump | Korea FLUTEK | ||

| Hydraulic Hose | Italy Manuli | ||

| Sealing Element | American Parker | ||

| Digital Electronic Control System | German Siemens | ||

| PLC Controller | Japan Omron | ||

| Proximity Switch | Germany | ||

| Intermediate Relay | Japan Omron | ||

| Button | France Schneider | ||

| Lubrication System | Full-automatic hydraulic | ||

| Discharging Port Diameter (mm) | Φ180 | ||

| Pipe (m) | 150 | ||