Electric Powered Concrete Pump

Electric powered concrete pump is designed with a hopper with optimized geometric angle and a super large mixing blade with reasonable blade angle, which significantly improve concrete suction capacity. With a plug-in one-way valve at both ends, the oil cylinder is able to replenish oil automatically. That is to say, every time the piston moves close to the end point of the stroke, the pressure oil will open the one-way valve and add oil for the loop oil circuit.

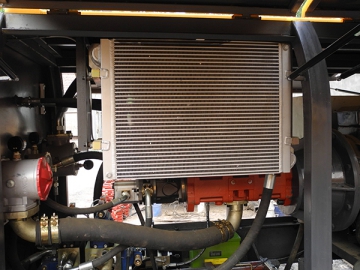

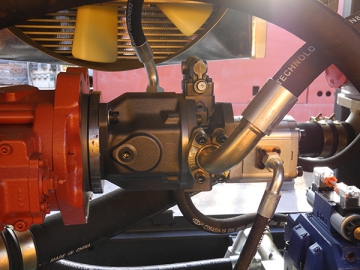

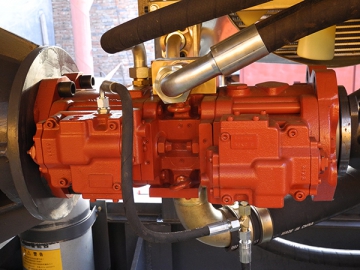

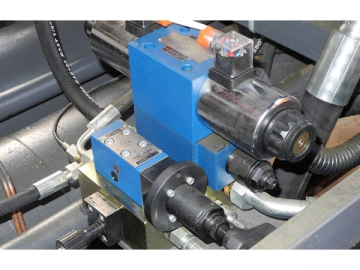

The hydraulic system of electric concrete pump consists of advanced elements and an electrical and hydraulic control system. The system also has sophisticated electric-hydraulic overload protection feature and an instrument display system. It also features easy operation, smooth movement, slight vibration and lower noise.

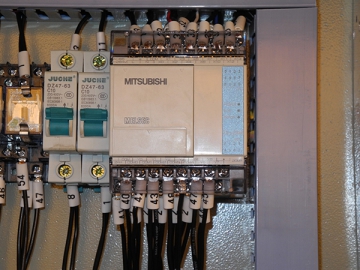

The pump also comes with advanced integrated electric control devices. Programmable controllers are adopted in control circuits. For the rest of electrical apparatus elements, we choose brand-name and high-quality elements. A lot of logic control work is accomplished by programmable controllers, which will simplify circuits and improve performance and reliability of the electric system at the same time.

The electric powered concrete pump is also designed with high-low-pressure switch feature, which means that users are able to adjust concrete displacement and pressure with the high-low-pressure switch-over valve according to requirements of specific construction sites, thereby achieving energy conservation.

The concrete pump is suitable for construction projects for water utilities, electrical systems, railways, highways, tunnels, bridges, ports, mines, high-rise buildings, and national defense. As an economical and practical conveying machine, it ensures high pouring quality. It is an ideal device for concrete delivery.

Other Images

| Model | |||||||

| Main Oil Pump Discharging Capacity (ml/r) | 112×2 | 112×2 | 112 × 2 | 140×2 | 100 | 100 | 112 |

| Motor Power (KW) | 90 | 90 | 110 | 110 | 37 | 37 | 45 |

| Master Cylinder Diameter/Stroke (mm) | Φ125/1650 | Φ125/1650 | Φ140/1800 | Φ140/1800 | Φ90/1000 | Φ 90/ 1000 | Φ100/1200 |

| Concrete Cylinder Diameter/Stroke (mm) | Φ200/1650 | Φ200/1650 | Φ200/1800 | Φ200/1800 | Φ160/1000 | Φ160/1000 | Φ160/1200 |

| Pumping Distance Horizontal/Vertical (m) | 800/200 | 800/200 | 1000/250 | 1000/250 | 400/120 | 400/120 | 600/160 |

| Discharging Port Diameter (mm ) | Φ180 | Φ180 | Φ180 | Φ180 | Φ125 | Φ125 | Φ125 |

| Random Delivery Pipe (m) | 150 | 150 | 150 | 150 | 100 | 100 | 100 |

| Main Oil Pump | Korea FLUTEK | 7313 Factory | Korea FLUTEK | ||||

| Hydraulic Hose | Italy Manuli | Shenyang NO.4 Rubber Plant | Italy Manuli | ||||

| Sealing Element | American Parker | ||||||

| Electronic Control System | France Schneider | ||||||

| PLC Controller | Japan Omron | ||||||

| Proximity Switch | Germany | ||||||

| Intermediate Relay | Japan Omron | ||||||

| Button | France Schneider | ||||||

| Lubrication System | Full-automatic hydraulic | ||||||