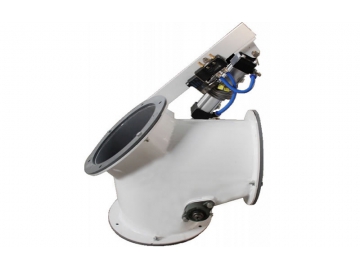

Pneumatic Diaphragm Control Valve

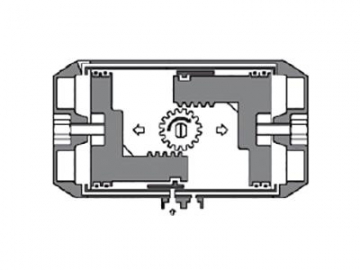

HG8400Q series pneumatic diaphragm control valve makes use of the inverted v-shaped protrusion between the diaphragm and valve body for sealing. The valve body is designed with simple and smooth flow path which can be coated with anticorrosive coating to ensure corrosion resistance and toxic resistance.

The pneumatic diaphragm control valve is available with 0.6 and 1.0MPa nominal pressure options. The valve body caliber ranges from 20 to 200mm. The pneumatic valve supports working under max. temperature of 150℃, and its leakage level is zero or VI.

We recommend clients choosing pneumatic diaphragm valves with fluorine lining.

Features

1. The pneumatic diaphragm control valve employs a multi-spring actuator, which ensures 30% reduction in height and weight.

2. The internal surface of valve body can be coated with various coatings, so as to avoid direct contact with mediums. This makes the pneumatic diaphragm valve compatible with corrosive or toxic mediums, and also makes it ideal for applications where environmental pollution should be avoided.

3. Simple flow path design ensures smaller resistance. The pneumatic diaphragm control valve offers higher rated flow coefficient than single-seat control valves or cage-guided control valves with the same caliber.

| Nominal Diameter (mm) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

| Rated flow coefficient Kv | Without lining | 9.8 | 19 | 32 | 48 | 63 | 108 | 158 | 270 | 360 | 518 | 1114 |

| With lining | 7.8 | 17 | 28 | 41 | 55 | 87 | 127 | 240 | 311 | 415 | 1121 | |

| Rated travel L (mm) | 8 | 10 | 12 | 16 | 21 | 30 | 34 | 36 | 44 | 55 | 65 | |

| Effective area of diaphragm Ae (cm2) | 280 | 400 | 600 | 1000 | ||||||||

| Piston diameter (mm) | 100 | 125 | 160 | 250 | ||||||||

| Nominal pressure PN ( MPa ) | 0.6 / 1.0 | |||||||||||

| Inherent flow characteristics | Approximate to equal percent | |||||||||||

| Working temperature ( ℃ ) | ≤150 ℃ | |||||||||||

| Signal range Pr ( KPa ) | 20-100, 40-200, 400-600 | |||||||||||

| Allowable leakage | Zero leakage or class VI, within allowable differential pressure range | |||||||||||

In addition to standard actuator, we can also design pneumatic diaphragm control valves with custom actuators.

Material of Main Valve Components| Name | Valve body | Diaphragm | Valve deck | Corrugated diaphragm | Spring |

| Material | HT200. ZG230-450 or come with lining made from above mentioned material | Butyraldehyde , natural rubber, Teflon | ZG230-450 | Polyester fabric reinforced nitrile rubber | 60Si2Mn |

| Valve body material | Lining material | Diaphragm material | Working temperature ℃ | Applications |

| Cast iron HT200 | Not available | Chloroprene rubber | 0-65 ℃ | Non-corrosive mediums such as water, abrasives, slurries, etc. |

| Cast iron HT200 | PTFCE | Fluororubber | -15-150 ℃ | Strong acids, strong alkalis, strong oxidants, and common organic solvents; Not designed for slurries |

| Cast stainless steel ZG1Cr18Niti | Not available | Fluororubber | -20-180 ℃ | Common acid, alkali and organic solvents |