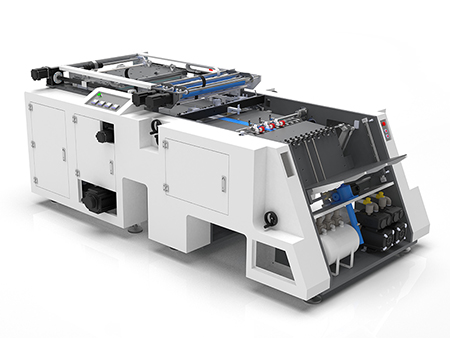

Intelligent Automatic Hot Foil Stamping Machine, LY-TJ720

Request a Quote

Designed for a broad spectrum of packaging uses, the automatic hot foil stamping machine is used for single-color flat foil stamping, registered embossing, 3D embossed foil stamping, etc. It performs rather well with several kinds of packing paper, including specialty paper, art paper, and fancy paper.

Sample Showcases

Foil stamping can be applied to a variety of materials, each chosen based on the packaging’s requirements:

- Single-color flat foil stamping

- Foil stamped with color in register

- 3D embossed foil stamping

- Embossing without foil

- Dual Channel Foil System: Supporting simultaneous two-color and multi-color foiling with various techniques including flat foiling with single color and color in register, 3D stamping, and embossing.

- Precision Accuracy: Packed with front lay, dual side lays, and laser sensors for high-precision positioning (±0.02mm accuracy), 720mm x 460mm as maximum stamping area.

- Adjustable Pressure: Uses a servo-driven pressing device with adjustable pressure up to 4.5 tons/cm². Depending on materials, pressure can be adjusted to get best results.

- Efficient Plate Change: Typically finished in 20 minutes, quick die changes are made possible by offset design between the platen and counter-pressure plate.

- Four-Zone Temperature Control: Adjustable temperature settings (60-150°C) cater to various paper materials for optimal foiling results.

- Paper Detection Sensors: Detects double sheets or missing paper, ensuring automatic paper collection after foiling is completed.

- High Capacity Feeding: Maximum pile height of 350mm. This CAM-driven feeder is able to reach 20 to 25 sheets per minute stamped speed.

- Versatile Application: Featuring a variable frequency suction mechanism, the feeding belt may be exactly changed to manage a wide spectrum of paper weights. This fits materials as thin as 80 gsm and guarantees best paper conveyance throughout the hot stamping operation. Appropriate for gift boxes, wine boxes, and more depending on the packaging use.

| Model | LY-720TJ |

| Paper size(L*W) | Max.: 720*500 mm |

| Min.: 260*120 mm | |

| Stamping size | Max.: 720*460 mm |

| Min.: unlimited | |

| Production speed | 20-25 pcs/min |

| Stamping area | 720*460 mm |

| Paper stacking height | 300 mm |

| Stamping pressure | 4.2 t/cm2 |

| Precision accuracy | ±0.02 mm |

| Max. stamping roll | 2 rolls |

| Max. diameter for stamping roll | 100 mm |

| Power supply | 380V |

| Constant power | 13 kW |

| Machine size (L*W*H) | 3000*1550*1000 mm |

| Machine weight | 4000 kg |

- Paper Feeder

- The paper feeding belt uses a variable frequency suction mode, which can be adjusted according to the weight of different paper materials during the hot stamping process.

- The paper feeding system is equipped with a sheet detection sensor to detect double feeding or missing sheets.

- High Precision Stamping

- Equipped with a front lay, dual side lays, and a laser sensor, with a stamping accuracy of ±0.02mm and a maximum stamping size of 720MM*460MM.

- Precise Temperature Control

- Four-zone temperature control allows for hot stamping of different paper materials. The temperature can be adjusted from 60 to 150 degrees Celsius.

Other Equipment of Rigid Box Line

There are some box making Equipment that we featured for choose your best