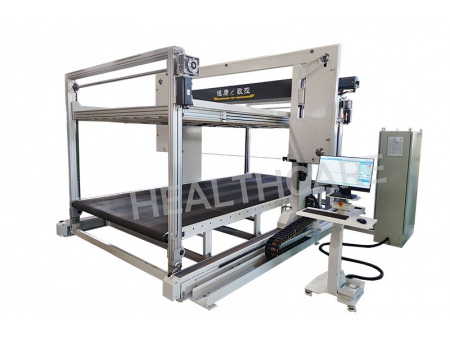

Horizontal Splitting Machine, CNCHK-QP

Request a Quote

Automatic Foam Splitting Machine for Cutting Foam Blocks into Sheets

Request a quote

Videos

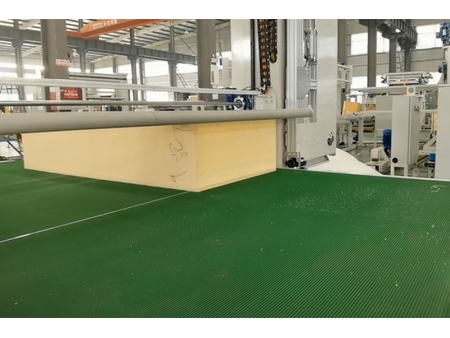

Horizontal splitting machine is mainly used for layered cut of ordinary foam, memory foam, industrial foam, etc. The cut foam materials are well stacked without human intervention. Featuring high accuracy and efficiency, this foam processing machine can be connected with vertical continuous blade contour cutting machine to form a cutting line, greatly improving working efficiency and reducing labor cost.

Contour Cutting Samples

Applications

- Foam fabrication

- Upholstered furniture

- Mattress

Materials

- PU foam

- Memory foam

- Rebond foam

Technical Data

| Machine size | 6700*4200*3750mm (blade on top) |

| Max. block size | 3000*2200*1250mm |

| Toothed blade | 10960*9.5*0.6mm |

| Cutting speed | 0-40m/min |

| Accuracy | ±1mm |

| Min. thickness | 10mm |

| Press roller | Installed |

Features

- Automatic foam size measuring

- Automatic knife feed and foam cutting

- One foam block can be cut into layers with 6 different thicknesses.

- Double-edge toothed blade

- Simple operation with touch screen

- Electric cable with good resistance to twisting and bending, ensuring improved service life of the cable

- Press roller works automatically by sensor.

- Set the desired thickness (different thickness) and quantity, no need make drawing.

- Absolute value of system, stable and reliable.

- Can be upgraded to an automatic cutting line.

Standard

- Press roller

- Foam measuring system

- Automatic feeding and cutting system

- CNC contour knives with double edged tooth knives

Options

- Extension table

- Vacuum device for lifting foam block