Coated Anticorrosion Steel Pipe

Coated Anticorrosion Steel Pipe

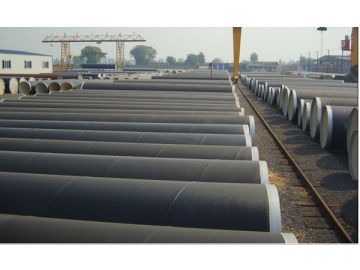

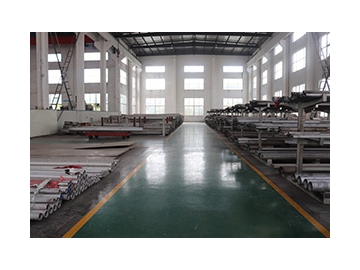

Apart from the ordinary steel tube and the related fittings, we can also produce the coated anticorrosion steel pipe according to customers’ requirements. With advanced steel tube anticorrosive technology available, the anticorrosion process can be conducted in our factory. Except for the ordinary anticorrosive paint spraying method, we also have the other four methods for steel tube anti corrosion.

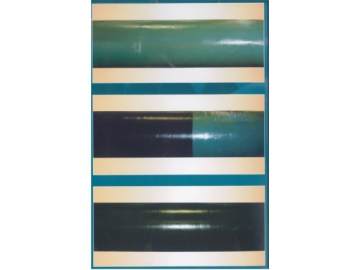

1. FBE epoxy powder anticorrosion coating. The epoxy powder is coated on the surface of steel pipe through electrostatic spraying process to form the anticorrosion coating at one time. This kind of anticorrosion coating has the merits of easy operation, no pollution, good resistance to impact, bending and high temperature, etc.

2. 3PE anticorrosion coating. Through electrostatic spraying, the epoxy powder is sprayed onto the surface of steel tube. Meanwhile, the adhesive and polythene anticorrosive coating are wound laterally onto the product. Together with the excellent performance of the three coatings, the coated anticorrosion steel pipe has remarkable performance in resistance to chemical corrosion, cathodic disbondment and mechanical damage.

3. Epoxy coal tar pitch coating. This kind of anticorrosive paint is made of epoxy resin, coal tar pitch and filler. It is coated on the surface of steel tube to form the anticorrosive coating together with the assistance of glass fiber fabric. This anticorrosive method is mainly applied for outer wall anti corrosion of steel tube.

4. Cement mortar lining. We can spray the cement coating through centrifuge or piping spraying machine in the inner wall of the water supply steel tube to protect the water quality.

Related Names

Corrosion Resistant Pipe | Anticorrosion Tube