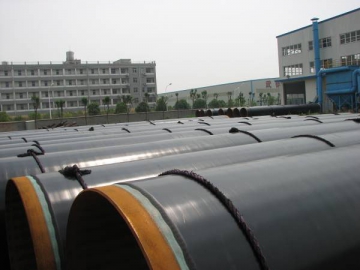

Natural Gas Transmission Steel Pipe

Natural Gas Transmission Steel Pipe

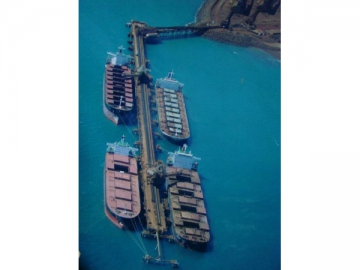

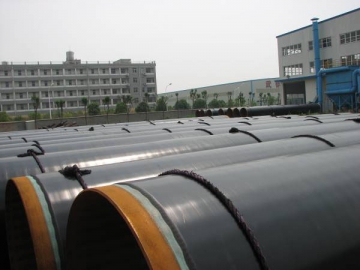

The natural gas transmission should be a continuous airtight conveying system. If any incident happens, the harmfulness is great and the affected area is very wide. So, the production of natural gas transmission steel pipe must follow rigorous requirements in welding performance, impact toughness, crack arrest property and other aspects. We can provide a series of reliable products comprising of spiral welded type and longitudinal welded type. The adopted materials for the product consist of Q235, Q345 and the pipeline steel with the steel grade ranging from A to X80. Meanwhile, all our products meet the standards of API SPEC 5L, GB/T9711.2, GB/T9711.1, SY/T5037, SY/T5040, GB50205, JTJ254, S311, AWWA C200, AS1579 and more. They have large diameter and can be widely used in the gas transmission trunk line of peri-urban areas.

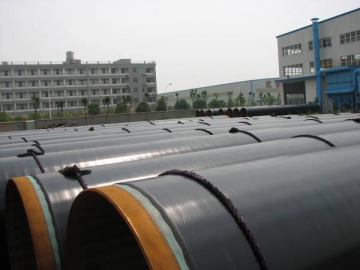

As to the pressure bearing capacity, there are no big differences between the natural gas transmissions steel pipes of spiral welded type and longitudinal welded type. However, in the aspects of stress corrosion and security, the longitudinal welded type is superior to the spiral welded type. The cost of the equipment for producing spiral welded product is low for the steel coil is much cheaper than the flat steel plate. So, the price of spiral welded type is significantly lower than that of longitudinal welded type.

The pipeline for transporting natural gas is very long. The cost for steel tube accounts for a large proportion of pipeline construction cost. To reduce the procurement cost as much as possible when constructing long-distance transmission pipeline, the spiral welded steel pipe is preferred to be used. Only when constructing short-distance transmission pipeline or the project is constructed with high requirements can the longitudinal welded type be chosen for guaranteeing high security and reliability. Customers can choose the product according to actual conditions.

There are mainly four corrosion damage ways for the natural gas transmission steel tube which are stress corrosion cracking (SCC), hydrogen sulfide corrosion, sulfide stress cracking (SSC) and hydrogen induced cracking (HIC). To avoid the SCC, we make the hardness of the product be HRC22 or HV248. Meanwhile, the sulfur, phosphor, carbon and manganese are limited with their contents less than 0.002%, less than 0.02%, no greater than 0.1% and no greater than 1.5% respectively. Then, the purity of the steel can be enhanced largely to ensure reliable corrosion resistance and long service lifetime. When lowering the content of sulfur, we conduct the calcium treatment. Through micro alloying, controlled rolling and cooling, the grain is refined and banded structure of the steel is restrained.

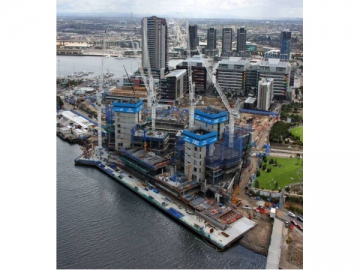

So far, we have provided the natural gas transmission steel pipes for Shanghai natural gas pipeline network project, pipeline reconstruction project of Shanghai Oil Refinery, Jinshan petrochemical engineering, coal gas pipeline project in Yinzhou District of Ningbo. Our products are praised highly by customers.

上海炼油厂管道改造工程 南美石油天然气项目

Shanghai Oil Refinery Pipeline Oil and Gas Project in South America

Reconstruction Project

Related Names

Natural Gas Pipeline | Steel Gas Piping