Offset Printing Machine

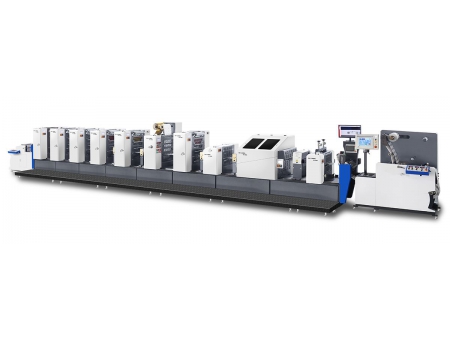

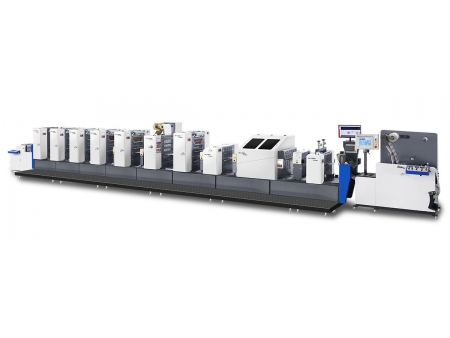

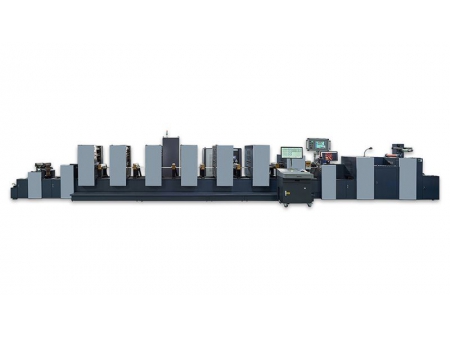

ZTJ-330 PS Plate Intermittent Offset Label Printing Machine

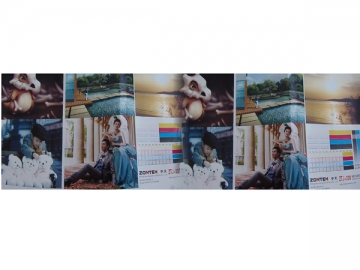

The ZTJ-330 offset printing machine is suitable for the printing of coated paper stickers, aluminum foil paper stickers, thermal paper, as well as PE, PP and PVC stickers. Its resolution is over 200LPI. The classic structure of Heidelberg SM52 is adopted and the three-point suspension mechanism makes this equipment more stable and practical.

Specifications

Max. Width of the Material | 330mm |

Max. Printing Width | 320mm |

Printing Length Range | 100-320mm |

Thickness of the Printed Material | 0.1-0.3mm |

Machine Speed | 30-200rpm(50m/min) |

Max. Diameter of Unwinding | 700mm |

Max. Diameter of Winding | 700mm |

Air Pressure | 7kg /cm2 |

Host Power | 30kw/6 colors (Not including the UV system) |

Power of the UV System | 4.8kw |

Power Supply | Three phase 380V |

Overall Dimensions | 9500×1700×1600mm |

Weight | about 9ton/6 colors |

Note: 1.Machine speed varies with the change of the printing length. | |

Combining German Heidelberg offset printing technology and our patent technology, the ZTJ-330 PS plate intermittent offset label printing machine adopts Japanese Panasonic servo motor and is controlled by DOS system and high-performance CPU. The self-developed vacuum reflux uncoiling technology solves the problem of unstable tension of traditional printers when printing and effectively prevents the depletion caused by fiction between printing materials and other components. This equipment is easy to operate. Users can control it through the mobile touch console to make it adjust by itself, like automatic pressure adjustment, ink roller cleaning, etc. Users can also add some devices, such as cold foil stamping system, CCD camera, etc., to make this equipment multifunction. Our product can run 200 revolutions per minute and can print on materials with the width of

Features

1. The ZTJ-330 offset printing machine adopts the most advanced ink system which has 23 ink rollers (including four large-diameter forme rollers) and uses alcohol dampening, ensuring the quality of the printed products.

2. Register can be adjusted through the remote control of each printing unit in transverse, longitudinal and skew directions without stopping the equipment. Movement of the printing unit is very flexible, so this saves time and reduces material waste.

3. Control system of the machine adopts imported international brands of electrical components, which guarantees long-term reliable operation.

4. Each unit is driven by independent servo motor, so each unit works independently of each other. A stable overprint precision can also be provided in high-speed printing.

5. For different printing length, it is only needed to input the printing specifications on the mobile console. Then each unit will automatically move to the required place, which is very convenient.

6. Adopting patented technology, our product can achieve greater variable-format printing.

7. The lubricating system is an automatic centralized refueling system.

8. The mobile touch console can move between units, so the working efficiency is improved.

Optional Devices

1. Automatic Ink Roller Cleaning System

2. Remote Ink Fountain Control System

3. Cold Foil Stamping System

4. Round Screen Printing Color

5. CCD Camera

6. Digital Printing Unit

7. UV Flexographic Printing Unit

The flexo printing with anilox is particularly suitable for UV varnishing and for making a white area on transparent materials.

8. Letterpress Printing Unit

9. Roller Die Cutting Device

The caring blade is attached on the magnetic drum and any graphic can be die cut.

10. Laminating Device

In high-speed intermittent printing, an intermittent laminating device can be installed before the roller die cutting device.

Reasonable Water-ink Transport Mechanism

Chamber Doctor Flexo UV Vanish Unit

Intermittent Silk Screen Printing Unit

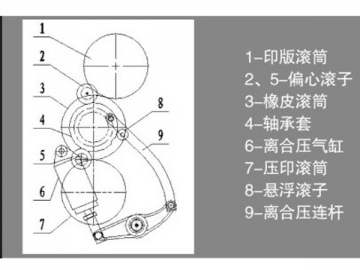

Three-point Suspension On-off Mechanism

1-*印刷滚筒 Printing Cylinder

2、5-偏心滚子 Eccentric Roller

3-橡皮滚筒 Blanket Cylinder

4-轴承套 Bearing Sleeve

6-离合压气缸 On-off Air Cylinder

7-压印滚筒 Impression Cylinder

8-悬浮滚子 Suspended Roller

9-离合压连杆 On-off Connecting Rod

Intermittent Rotary Die Cutter Unit

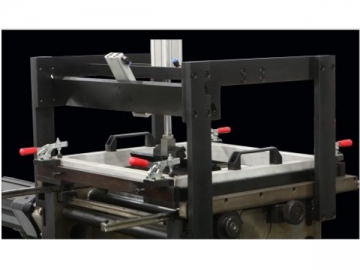

Vacuum Paper Feeding System

Easy and Quick Paper Connect System