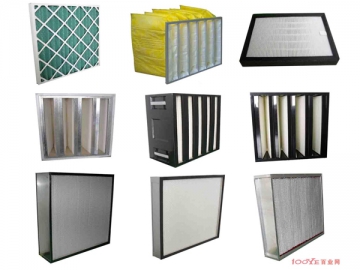

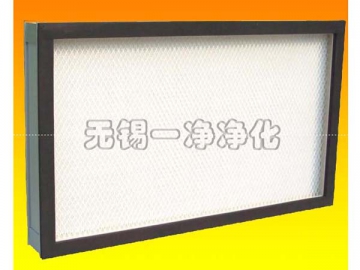

Clean Room HEPA Filter

Class EN 1822 | H11 | H14 | H15 |

Filtration Efficiency (%) | >95 | >99.995 | >99.9995 |

Surface Air Speed (m/s) | 0.5 | 0.5 | 0.5 |

(Pa) D=50 | 72 | 147 | 210 |

Initial Resistance (Pa) D=65 | 48 | 99 | 147 |

Outside Dimension and Air Volume

Length (mm) | Width (mm) | Air Volume (m³/h) |

305 | 610 | 287 |

610 | 610 | 605 |

760 | 610 | 762 |

915 | 610 | 924 |

1220 | 610 | 1242 |

1170 | 570 | 1108 |

1170 | 870 | 1724 |

1170 | 1170 | 2340 |

Features

1. When the dimension and the weight of the clean room HEPA filter are reduced, the air volume can be increased.

2. We can produce the product with much larger air volume to meet the needs for air speed and working space.

3. In order to facilitate moving and installation, the outer frame of the product can be smaller in size and weight to reduce the weight of product.

4. The excellent design can allow flexible installation, replacement and upgrade for the product.

5. The performance of the filter is more excellent than that of product with baffle and outer frame two times of the HEPA product in height.

6. The product with the pleat height of 55mm, 70mm and 75mm can reduce the resistance and improve filtration efficiency of the product. Meanwhile, it can bring the benefit of energy saving.

7. The applicable humidity for the product can be up to 100% and the maximum temperature is 85°C.

Every set of HEPA filter is inspected at foreign enterprises and 3% of the products would be found unqualified. Most of the unqualified products can be repaired to the qualified products and the left 1% unqualified products cannot be repaired. After testing the domestic product just off the assembly line, the failure rate can be 3% to 10% even up to 30%. The actual condition is that only 10% of the domestic manufacturers have the professional inspection equipment and that the manufacturers adhering to inspecting every set of the product are very little. Many untested products come into the market directly.

Visual observation cannot find the defect of the HEPA filter. For the occasion with high cleanliness, one such unqualified product can cause failure to the whole project. So every set of product should be inspected with the special test bench strictly. However, the inspection for every set of the product would increase the production cost for the testing expense and the cost of unqualified product. So the price of the qualified product would increase accordingly.

Our HEPA filter is manufactured in the workshop with high cleanliness. Before being delivered away, every set of our product must pass the standard inspection. With high quality available, our product has been welcome by the customers at home and abroad.