Case Study of Flat Belt

Request a Quote

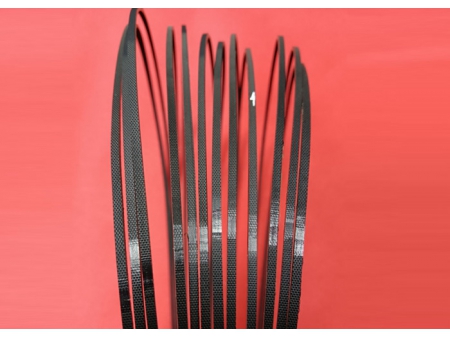

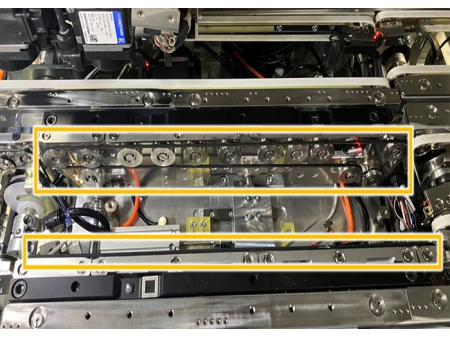

Flat belt with burr-free edge used in the automation equipment from YAMAHA and HUAWEI

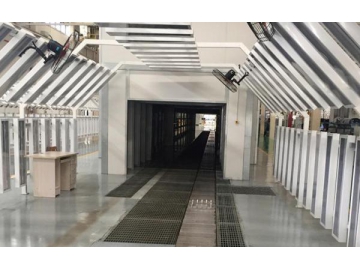

Introducing Dongji Belting, the provider of the world's first flat belt featuring high antistatic and high-temperature resistance, coupled with a butt-free edge. Our belts are trusted and employed in the automatic machinery and equipment of YAMAHA in Japan and HUAWEI in China.

Dongji has developed a flat belt with burr-free edge that has successfully passed both static physical performance tests in our laboratory and dynamic tests under installed load conditions conducted by our customers. Our flat belt offers exceptional performance and meets all of our customer's design and application requirements. Here are the five key advantages:

- Designed to be burr-free during use.

- Meets the highest ESD and ROHS standards in Europe, America, and Japan.

- Operate continuously in temperatures ranging from -30 ° C to 130 ° C, making it ideal for high-temperature machine equipment used after processing or treating materials in a high-temperature furnace.

- Superior to other flat belts of the same thickness, our flat belt with burr-free edge has higher tensile strength, greater bearing capacity, and lower elongation.

- Our flat belt is highly flexible and adaptable to any environment. It is also compatible with small wheel diameters, and the belt pulley won't come loose even with repeated use.

Specifications of flat belt with burr-free edge

- Belt thickness of NBB series:0.8/1.0/1.2/1.5/1.8/2.0mm (± 0.1mm)

- Standard width:500 mm (the size of the connected belt can be customized as required)

- Interface mode:grinding connection (with installation direction)

- Application:Transportation of electronic articles in the electronics industry

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos