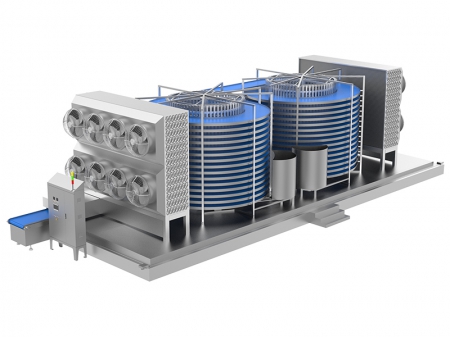

Double Spiral Quick Freezer in Thailand

A high-efficiency pre-cooling and quick-freezing solution designed for optimal storage in fish processing plant in Thailand

- Utilizes a 20-ton high-efficiency flake ice machine to rapidly produce ice, utilizing its large contact area to absorb heat quickly from the fish. This ensures rapid pre-cooling, inhibiting bacterial growth, and providing the first line of defense for food safety.

- A customized straight-line double spiral quick freezer is designed to fit the customer's facility. With a compact layout, it maximizes space efficiency while delivering exceptional freezing performance. The freezing system rapidly reduces the temperature of fishery products to below -18°C, effectively preserving freshness, nutritional value, and texture.

Suitable for quick-freezing whole split fish, single-side fillets, and fish portions

- Pre-cooling system: 20-ton flake ice machine

Flake ice is widely recognized for its ease of storage and transport, making it highly adaptable for various preservation needs. With rapid ice production and superior cooling performance, flake ice enables efficient pre-cooling while ensuring uniform cooling distribution, effectively inhibiting bacterial growth.

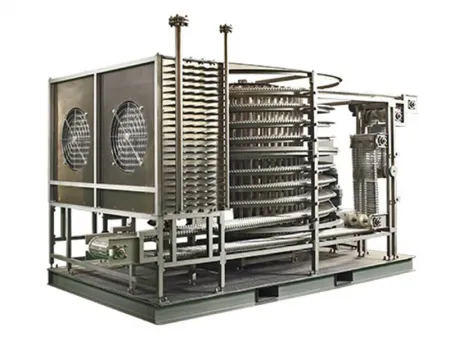

- Equipped with a parallel system of three Bitzer compressors, ensuring highly efficient refrigeration and stable long-term operation.

- Optimized for tropical climates and coastal water conditions, the system incorporates evaporative cooling technology with a corrosion-resistant stainless steel evaporator, maintaining high heat exchange efficiency and stable performance even in high-temperature, high-corrosion environments.

- A 10-ton ice storage bin is integrated beneath the flake ice machine, constructed with polyurethane sandwich panels and 304 stainless steel outer surfaces for superior insulation which utilizes off-peak electricity to produce and store ice efficiently for on-demand supply.

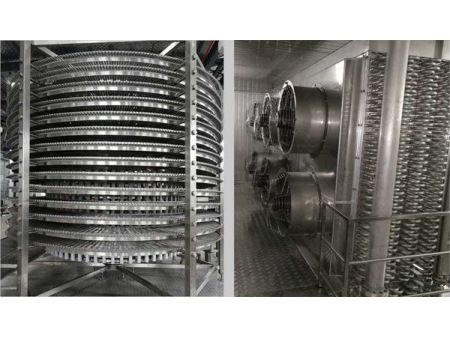

- Double spiral quick freezing system

The double spiral quick freezer consists of an insulation system, transmission system, and heat exchange system and is custom-designed to fit the client's facility layout. Featuring a first-in, first-out linear flow design, it optimizes space efficiency with its compact structure while ensuring exceptional freezing performance. With a highly automated operation, it rapidly reduces the temperature of fishery products to -18°C or below, preserving nutritional value, texture, and freshness, ultimately enhancing their overall market competitiveness.

- Insulation system

Constructed with stainless steel polyurethane sandwich panels, forming a well-insulated enclosure with a density of 42kg/m³, the storage unit measures 9150mm in length, 3850mm in width, and 3550mm in height and is equipped with low-temperature explosion-proof LED lighting for safe operation. The cold room door features a self-regulating heating system and a magnetic sensor switch, ensuring safe and reliable operation by keeping the door consistently functional. The floor structure is made of welded stainless steel, designed with built-in drainage channels on both sides and a slightly elevated center section to create a slope toward the drains. Four drainage outlets facilitate the rapid removal of condensation, reducing downtime and improving operational efficiency.