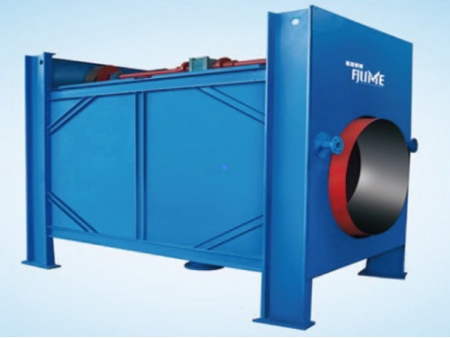

Drum Screen

HONGJI drum screen consists of motor, decelerator, rotordrive, chassis, seal cap, inlet and outlet.

After material is fed into the drum, it will be lifted up by the rotation and aerated as it falls back down. This action repeats with each revolution along the length of the drum. At last, the finer material passes through the screen openings while the larger material tumbles towards its eventual exit at the rear of the drum.

Features

1. The drum screen is configured for classification, screening and grading.

2. With its simple structure, it operates with higher reliability and low investment cost.

3. The drum screen is easy in maintenance.

4. Smooth running and low operational noise

5. As a result of its unique screen design, the drum screen is characterized by higher capacities, longer screen life and less blocking of mesh screen.

This drum screen can be used in different industrial fields for different purposes.

1. The drum screen is suitable for screening and classifying gravel, clay, mountain meal, sand, etc.

2. It is also commonly used in coal industry for screening and classifying lump coal, coal dust, coal washing, etc.

3. In chemical and mineral-selecting industry, the drum screen is ideal for grading and classifying lump, powder substance, etc.

4. Additionally, it is widely used in metallurgy, construction and other industries.

Technical Parameters

| Model | Capacity(m3/h) | Drum Diameter(mm) | Length(mm) | Power(KW) | Overall Dimensions(mm) |

| 20-50 | Φ1200 | 3000 | 3 | 3580×1590×1675 | |

| 40-80 | Φ1500 | 3000 | 5.5 | 3980×1790×1975 | |

| 80-150 | Φ1800 | 3000 | 7.5 | 4150×1870×2240 | |

| 130-200 | Φ2000 | 3000 | 11 | 4230×1950×2950 |