Metal Fabrication Equipment

Without advanced metal fabrication equipment, there is no quality metal fabricating service to speak of. YunPeng invests in a complete rang of metalworking equipment to meet customers’ differing needs.

That equipment includes the punch press, hydraulic press, NC press brake, NC plate shear, NC punch press, laser cutter, arc welder (with argon as shielding gas), welding machine with carbon dioxide as shielding gas, lathe, NC milling machine, NC drilling machine, NC machining center, gantry milling machine, gantry planer, wire-cut EDM machine, grinding machine, and drilling machine, totaling more than 30 types.

We own and operate various stamping presses in load capacities from 16t to 500t. Material thicknesses we can handle range from 0.3mmm through 16mm. Stamping precision is maintained within /-0.02mm. Various stamping needs can be met.

By changing in and out different stamping dies, we can stamp different kinds of piece parts.

On the hydraulic press, metal blanks are drawn (pulled) into a die cavity via a process known as deep drawing to produce various hollow parts or form hollows parts into different shapes.

According to the nature of deep drawn parts, we will add a protective film to the surface of workpiece for protecting zinc coating from being damaged during deep draw.

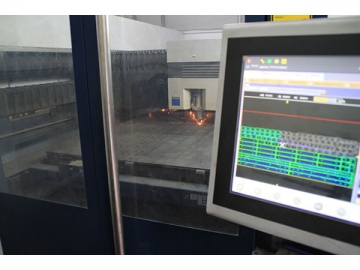

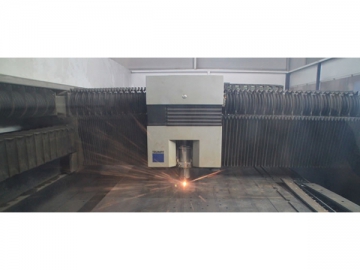

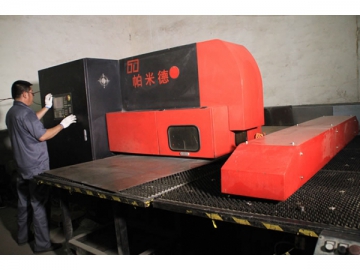

Trulaser 3030 laser cutter, imported from Germany, comes with a 4kw laser device that easily cuts 20mm-thick carbon steel plate. Linear motor allows the laser cutter to exhibit excellent dynamic performance and fast cutting speed. A change table can be mounted along the machine direction so that operators can walk shorter distance to change workpiece easily all while reducing walking time.

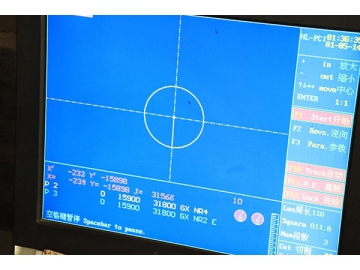

Highly trained operators are setting programs for precision cutting.

TruLaser 3030 uses one single cutting head to cut all types of plates that fall within its cutting capability. The machine cuts automatically according to preset cutting programs.

Finished products feature a very smooth surface suitable for use in various sheet metal fabrication operations.

With a nominal pressure of 1000KN, the NC press brake can bends plates as long as 3000m. It can meet various metalworking needs.

- Operators are setting programs for plate bending operation.

- Bending process

- Bending process

- Bending process

- Bend results comparison

- Bend results comparison

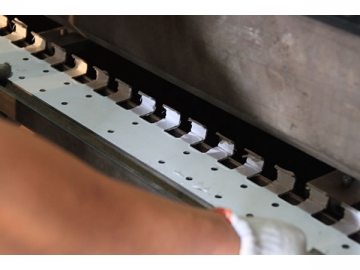

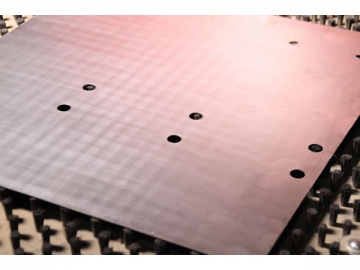

A high level of automation allows our NC punch press to make quick work of punching operation on metal plates measuring 1250mm by 2500mm in dimension and with thickness up to 6mm.

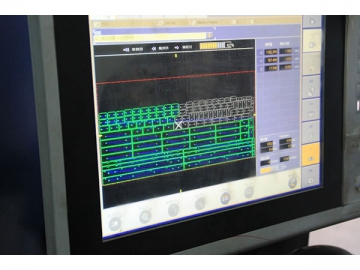

Automated programming software converts a piece part design into an executable program automatically. It generates processes that control every stage of operation including automatic cut-out, clamp avoiding collision with press tool, and optimizing material usage.

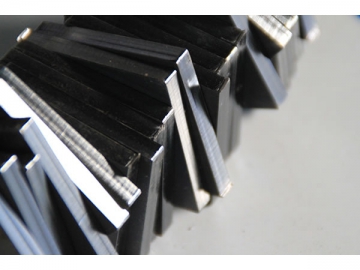

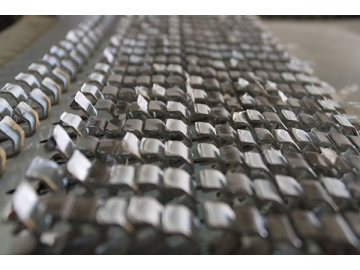

The machine table uses either brushes or a combination of brushes and steel balls to reduce sheet metal surface scratch and lower noise when the sheet is moving. The use of heavy-duty turret allows precise punch to die alignment and gives the punch press extra ability to withstand side load.

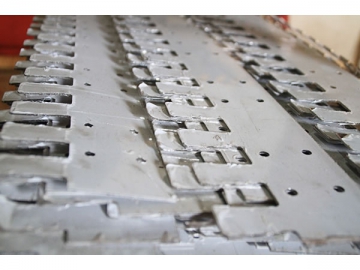

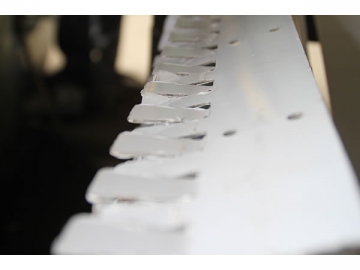

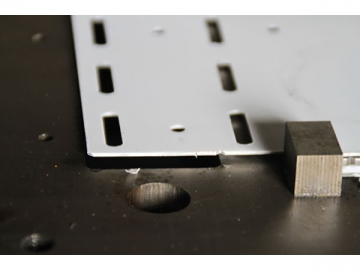

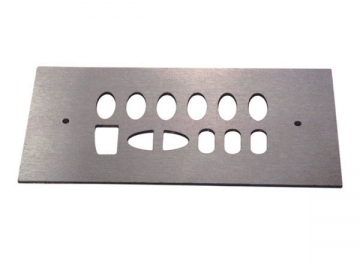

Punched metal sheets with holes distance tolerance of±0.1

CNC hydraulic swing beam shear cuts metal plates to precise lengths.

Maximum plate width: 3200mm.

Maximum plate thickness: 6mm

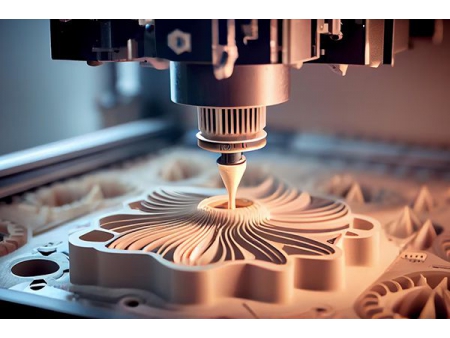

A vertical machining center is used to deliver high machining accuracy of ±0.01mm. The entire machining process is numerically controlled to meet the exact machining needs of customers.

- Operators measures machined parts against the design requirements.

- In-process parts. Easily replaceable tools

- NC lathe, wire-cut EDM machine

- NC lathe, wire-cut EDM machine

- NC lathe, wire-cut EDM machine

Come to YunPeng when you have tough metal fabrication jobs on your hands. Our metalworking capabilities make sure you get satisfactory custom parts every time.