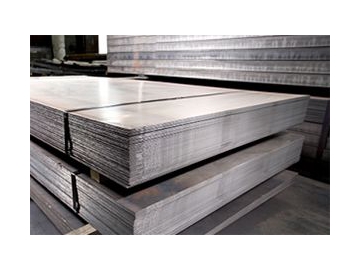

Sheet Metal Fabrication

Sheet metal fabrication most typically works on thin sheets of metal and bends them into desirable shapes and sizes manually or with the aid of presses, tools and dies. Welding or other mechanical work may follow after the process to work parts with more complex geometries.

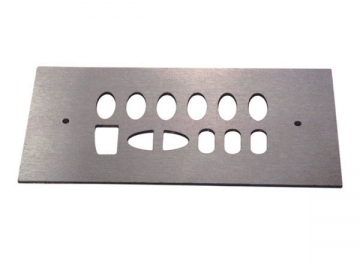

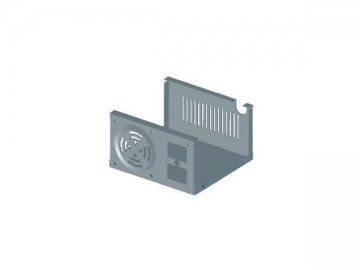

Custom parts can are manufactured through sheet metal fabrication include car panels, equipment housing, and protective enclosures. We can fabricate those components from a variety of materials, including carbon steel, stainless steel (steel grades 303/304/316/430), aluminum and aluminum alloy, copper and copper alloy, etc.

Material Thickness : 0.3mm-6mm

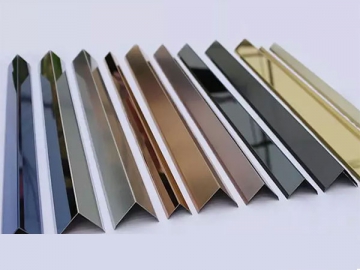

Surface Treatment : Galvanizing, chrome plating, nickel plating, spray painting, polishing, hairline finish, oxidation

Equipment Used

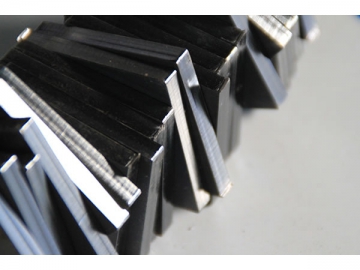

Plate shear, NC punch press, laser cutter, NC press brake, welding machine

Laser cutter will be used when handling small volume production runs requiring high accuracy on large, complex parts. Laser cutting saves time, reduces production costs, and improves cut quality.

Productivity: 30T/Month

Sample Cycle Time: 15 days

Product Cycle Time: 25 days

Packaging: Paper box, pellet, wooden crate, or as per customer requirements

Quality Control, Inspection: Measures up to ISO9001 standards