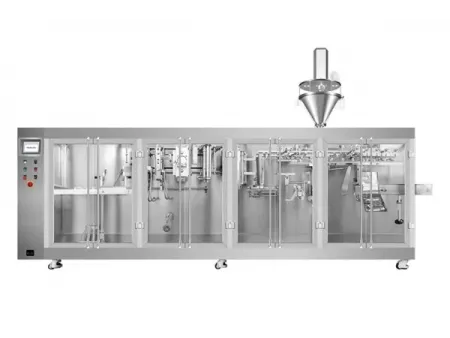

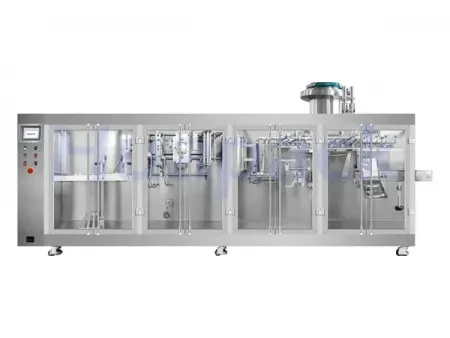

Flat Pouch HFFS Packaging Machine, 1-Nozzle Filling

Horizontal form fill seal machine

These HFFS flat pouch packaging lines work with rollstock film and handle the full process in one continuous flow, including pouch forming, dosing, cutting, opening, filling, sealing, and weight control. The mechanical structure and control system work together so the packaging machine runs smoothly without frequent stops, keeping movements well synchronized and allowing production to stay steady at around 40 pouches per minute. These rollstock flat pouch packaging system are suitable for small-volume products such as pharmaceutical powders and grains, as producers need a line that can run steadily, handle large quantities, and keep packaging costs under control.

- Film unwinding

- Film alignment

- Film forming

- Easy-tear notch unit

- Bottom sealing

- Vertical sealing

- Hanging hole punching

- Cutting

- Pouch gripping

- Pouch opening

- Filling

- Heat sealing

- Cooling sealing

- Finished pouches

- Finished pouch conveying

| Performance features | Rollstock flat pouch parameters | | | |

| Pouch parameters | Min. pouch size | 60x80mm | 70x130mm | 75x85mm |

| Max. pouch size | 130x180mm | 180x225mm | 240x225mm | |

| Filling volume | 160ml | 400ml | 1000ml | |

| Packaging speed | ≤60 | ≤60 | ≤50 | |

| Rollstock film thickness | 70-150u | 70-150u | 70-150u | |

| Max. rollstock film outer diameter | 500mm | 500mm | 500mm | |

| Machine specifications | Rollstock film core inner diameter | 70-80mm | 70-80mm | 70-80mm |

| Machine dimensions (L × W × H) | 2850x920x1460 | 3500x970x1450 | 4500x970x1460 | |

| Machine weight | 1500kg | 1800kg | 2100kg | |

| Operating conditions | Operating temperature | ﹣10℃- 50℃ | ﹣10℃- 50℃ | ﹣10℃- 50℃ |

| Operating humidity | Less than 85% | Less than 85% | Less than 85% | |

| Power supply | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | |

| Air pressure | 0.6Mpa | 0.6Mpa | 0.6Mpa | |

| Air consumption | 200L/min | 200L/min | 300L/min | |

| Main drive power | 3.5kw | 5kw | 5.5kw |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

A veterinary pharmaceutical producer in Malaysia added the 180N rollstock flat pouch packaging machine to their plant in 2024 for packing pouches with capacities that range from 40 g to 70 g. Since starting up, the rollstock flat pouch packaging machine has been running smoothly in daily production, and our client has been satisfied with both filling accuracy and overall performance.