Liquid Crystal Module (LCM) Pin Coating Solution

Industry Background:

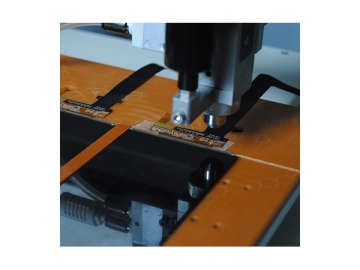

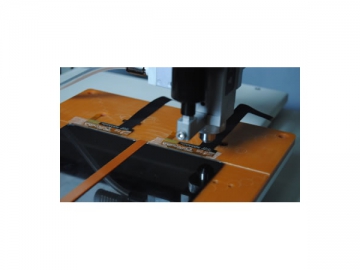

After the FOG processing, the liquid crystal display module needs to be glue coated for dust-proof and water-proofing on the press connection. The FPC broken line also needs to be glued to avoid link breakage in assembly.

Technological Features:

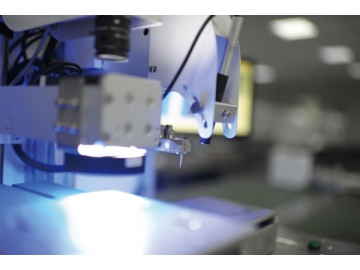

Liquid crystal display modules are the key factor to improve the yield in the production process. With the development of automation technology, the requirements on coating effect become easier to reach.

Main Difficulties in the Production of Ultra Narrow LCD frames

1. Slow operating speed

2. The uniformity and consistency of glue coating

3. Harmful to human skin

Solution Advantages:

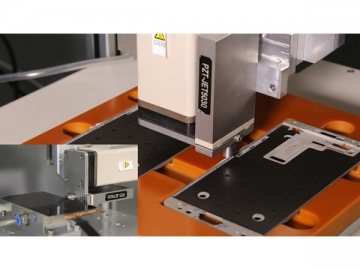

1. Mingseal DS series B type tri-axis coating equipment, economical and practical

2. Functions of glue breaking, anti drawing, anti curing, automatic fillet transition, smart array, etc.

3. Ensure the uniformity and consistency of glue coating

Solution:

DS-300B dispensing robot dispensing cylinder/valve dispensing controller

Related Products:

DS-300B dispensing robot, glue cylinder, dispensing valve, DC-200Cdispensing controller