LES Eddy Current Separator

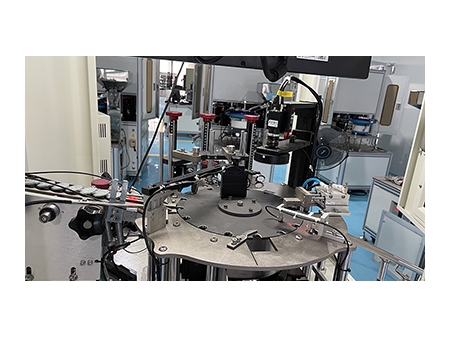

Features

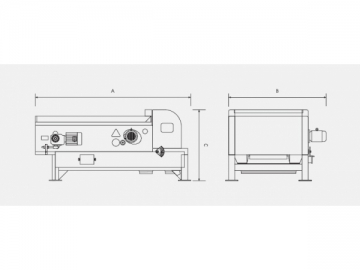

1.Compact design allows for a minimal footprint

2.Easily adjustable rotor and pulley speeds allow for maximum efficiency

3.Easily adjustable baffle to ensure proper separation

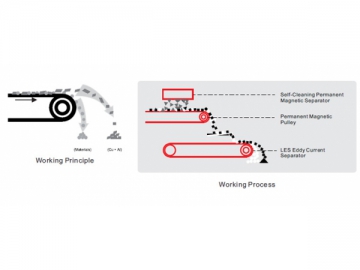

Brief Description of Operation

1.The LES eddy current separator (ECS) was designed on the basic theory that an inductive current generates inside a conductor while it is in a state of a high frequency, alternating polarity, magnetic field. When the conductive material reaches this stage in the ECS an eddy current is formed. The alternating polarity causes the conductive material to be forced away from nonconductive material and it is “thrown” forward and away from the other materials.

2.This allows for an efficient separation by allowing the single stream to be split into two and the materials can be recycled very effectively. LONGi offers multiple styles and designs. Based on the customer's specific needs either a concentric or eccentric rotor may be recommended as well as different belt and rotor speeds and sizes

3.When used in such industries as MURF, auto shredders, nonferrous yards, Escrap and the plastic industries, the ECS can be a great addition to either recover the higher priced metals or remove them as a contaminant from the primary stream.

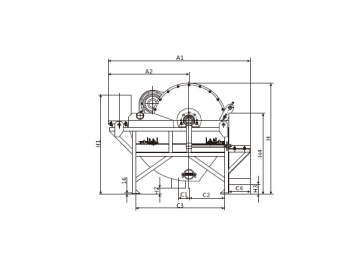

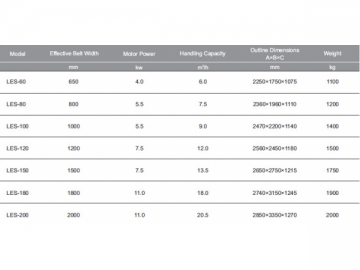

Technical Parameters

Longi is a reliable eddy current separation machine manufacturer, equipment for non-ferrous metal filtration. Our company focuses on making separation magnets as well as tramp metal separation solutions for customers. Longi Magnet Company is a trustable magnet separation equipment manufacturer since 1993, there are also wet drum and dry drum separators provided with high efficiency.