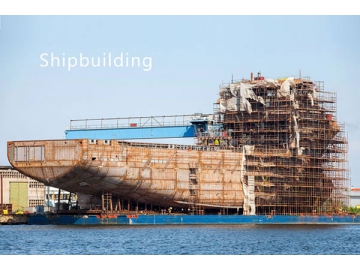

Marine Steel Deck Cutting

The structural steel used in constructing ships usually contains .18% to .23% of carbon, classifying it as low carbon steel. Because each marine steel deck is uniquely shaped and quite thick, manufacturers generally prefer acetylene gas for cutting, but the cutting requirements of marine deck steel and the advantages of using oxy-hydrogen gas may make you choose our oxy-hydrogen equipment.

Cutting Requirements

1. Oxy-hydrogen pressure must be properly supplied at a low volume so the ferric oxide slag won't be blown away. If the pressure is too high, the cutting edge will become wider and coarser.

2. Preheating the flame's energy rate should be monitored. If too high, the cutting edge will melt. If too low, the cutting process will be interrupted, creating a jagged, rough cutting edge.

3. The cutting speed should also be carefully selected. If too fast, the metal plate will lag and be difficult to cut through, causing the iron slag to burst or backfire. If too slow, the ends of the steel plate may melt more easily, causing sparks to fly backward, or deform and waste material.

4. The cutting torch should be kept clean and without iron slags on the cutting head. The holes inside the cutting head especially should be kept smooth.

5. Since traditional acetylene gas has a large energy cost, easy flame dispersion, and difficult speed control while contributing to environmental pollution and being unable to guarantee the cutting quality, oxy-hydrogen has gradually replace acetylene as a superior heat source.

Advantages of Using an Oxy-Hydrogen Generator to Cut Marine Steel Decks

1. At low pressure, it's easy to control the cutting speed of the clean energy product.

2. A smooth cutting edge reflects metallic luster and without a nitridation layer, the workpiece can be directly welded after cutting.

3. No slag on cutting lower edge: The exothermic reaction of oxygen and iron upon cutting produces extra heat and FeO slag, which has a lower surface tension that makes cutting more fluid and smooth and forms a smaller cutting edge bevel.

4. Our oxy-hydrogen machine has a smaller heat effective zone which reduces the chance of deformity in cutting and improves cutting precision.

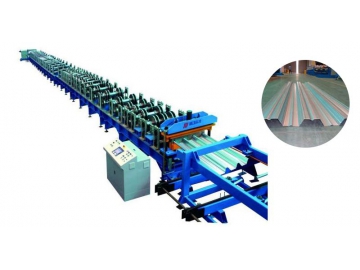

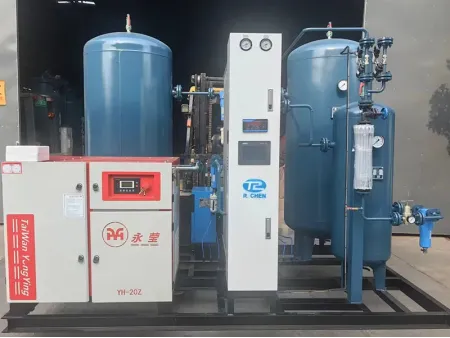

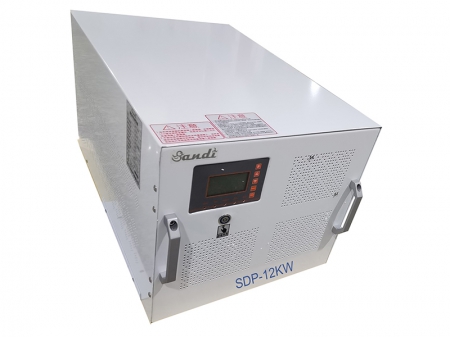

Recommended Products