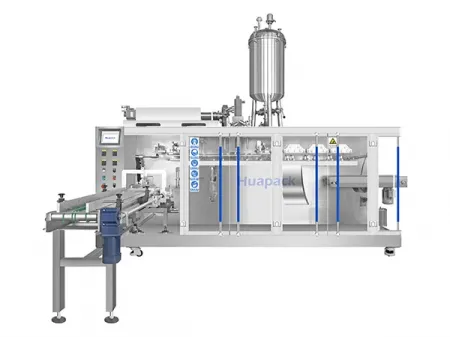

Premade Pouch Packaging Machine, 1-Nozzle Filling

Designed for larger premade pouches up to 2000 ml, these single-nozzle packaging machines are suitable to handle formats that are usually hard to separate, such as stand-up (doypack) pouches, zipper pouches, and spouted pouches. The pouch packaging machines are equipped with a separating system that splits tightly stacked bags one by one and feeds them smoothly to the grippers, reducing issues such as sticking, mispicking, or line stops caused by slippery materials or complex pouch shapes. These pouch filling machines can handle everything from simple flat pouches to more complex shaped and 3D ones, feeding them one by one in a steady way. All steps, pouch separation, opening, filling, and sealing, move in a steady and well-coordinated way, even when working with larger pouch sizes and higher filling volumes.

Applications

Supported Pouch Types

- Flat pouches

- Flat pouches

- Stand-up pouches (doypack)/Zipper pouches

- Stand-up pouches (doypack)/Zipper pouches

- Pouch loading

- Pouch pick-up

- Pouch opening detection

- Bottom opening

- Filling

- Pouch spreading

- Heat sealing

- Seal cooling

- Finished pouch forming

- Finished pouch discharge

| Model | 240NG-F |

| Pouch width range | 80–240 mm |

| Pouch length range (stand-up pouch) | 90–350 mm (130–350 mm for stand-up pouches) |

| Max. filling volume | 2000ml |

| Machine dimensions | 2880 × 1100 × 1400 mm |

| Operating temperature | −10 °C to 55 °C |

| Max. operating humidity | Below 85% |

| Power supply | AC380V, 50HZ |

| Air pressure | 0.6Mpa |

| Air consumption | 350L/min |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

In 2025, a company in Guangzhou that specializes in household and personal care products chose our premade pouch packaging solution for packing 1 kg laundry detergent pods. The pouch packaging machine we offered them is now used in their production line to handle these larger packs smoothly, keeping the filling and pouch handling stable for this type of heavy, viscous product.