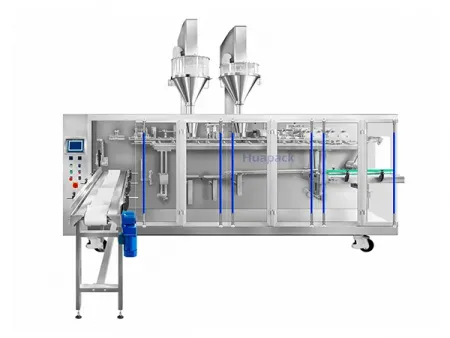

Premade Pouch Packaging Machine, 1-Nozzle Filling

Suitable for medium-volume filling up to 3000 ml, these 1-nozzle premade pouch packaging machines feature a stable output of around 40 pouches per minute while keeping a compact footprint on the production floor. The servo system guides each stage of the process, from picking and opening the pouches to filling and sealing them, keeping all movements smooth and well-coordinated. The hopper and filling range are designed for filling volumes of up to 3000 ml, so operators do not need to stop the line often to add product. Components from renowned brands such as Siemens are used in the pouch packaging system, which gives the equipment the stability it needs to run for long shifts without constant adjustments or unexpected shutdowns.

Applications

Supported Pouch Types

- Stand-up pouches (doypack)/Zipper pouches

- Stand-up pouches (doypack)/Zipper pouches

- Shaped pouches

- Spouted pouches

- Pouch loading

- Pouch pick-up

- Pouch opening detection

- Bottom opening

- Filling

- Pouch spreading

- Heat sealing

- Seal cooling

- Finished pouch forming

- Finished pouch discharge

| Model | 280NG |

| Pouch size range | (Min.) 90x130mm (Max.) 280x400mm |

| Max. filling volume | 3000ml |

| Packaging speed | ≤40 |

| Machine dimensions (L × W × H) | 3200mmx1100mmx1500mm |

| Machine weight | 1500kg |

| Installed power | 5.5kw |

| Air consumption | 350L/min |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

A nutraceutical producer from the Netherlands chose our 3000ml pouch packaging solution for filling protein powder in packs with sizes ranging from 100 g to 2 kg. The premade pouch packaging equipment we offered them was configured to handle stand-up pouches with zippers, meeting the client’s requirements for both flexible pack formats and consistent filling accuracy.