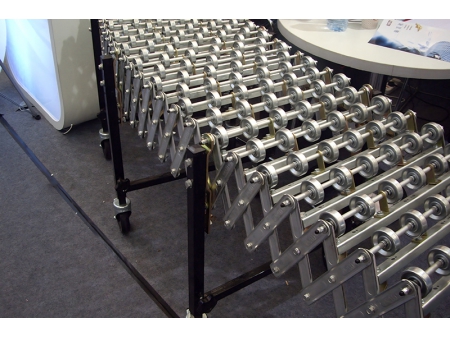

Roller Telescopic Conveyor

Request a Quote

Roller telescopic conveyor is an automated conveying device with adjustable length, generally composed of a fixed section and a telescopic section. It is widely used for loading, unloading, and transferring carton products.

Standard specifications- Frame: 50 mm × 59 mm square tubes 3 mm steel plates

- Roller diameter: 50 mm

- Dimensions: Customizeable length & width

- Flexible Scenario Adaptability: The length adjustment range varies from a few meters to several tens of meters (e.g., 5 m to 30 m), adapting to various loading and unloading distances. Some models also feature adjustable angles to match various dock heights.

- High Automation Efficiency: Reduces manual handling, improving loading and unloading efficiency by 30%–50%. Additionally, the roller telescopic conveyor can be integrated with sensors or PLC control systems for automated operation.

- Space and Cost Savings: When retracted, the conveyor only occupied 1/3–1/2 of the extended length’s space. This conveyor can replace multiple fixed conveyors, reducing procurement and maintenance costs.

- Versatile Functionality: Available in belt, roller, or chain plate conveying types, and equipped with anti-slip and anti-deviation designs to ensure stable transportation.

- Safe and Energy-Efficient: Equipped with emergency stop buttons and protective guards, the on-demand extension reduces energy consumption by approximately 20% compared to traditional conveyors.

- Easy Direction Change: The conveyor offers a maximum turning angle of up to 180°. It is equipped with casters for convenient movement, and lifting mechanisms allow height or inclination adjustment, combined with electric rollers or micro motors for reduced operating effort.