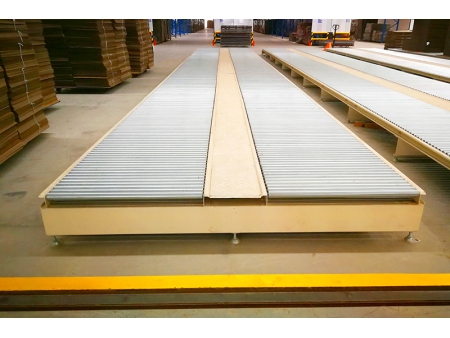

Gravity Roller Conveyor

Request a Quote

Gravity roller conveyor is a basic corrugated board conveying solution composed of freely rotating rollers arranged in parallel. It relies on material weight or manual push for movement. Designed for buffering, loading/unloading, and lightweight stacking and conveying, this roller conveyor requires no power drive and offers a simple and reliable structure. This conveyor can be flexibly assembled into linear, curved, or inclined/declined conveyor—ideal for low-cost flexible logistics systems in carton plants.

- Zero energy Consumption: Purely mechanical design with no power usage and minimal maintenance cost, offering high return on investment.

- Flexible Modular Layout: Supports straight lines, curves, and inclined/declined conveyor sections, with adjustable roller spacing of 50–100 mm, suitable for cardboard of different sizes.

- Efficient Light-Load Transfer: Galvanized steel rollers with precision bearings provide sliding resistance of ≤5 N/m, enabling a single person to easily push the entire board stack and increase cardboard-handling efficiency by 200%.

- Environmentally Friendly: Made of recyclable materials free from oil pollution, especially suitable for clean workshops with high environmental standards.

- Roller material: Galvanized steel/stainless steel/plastic (optional)

- Roller diameter: Ø50/Ø60/Ø76 mm

- Load per roller: 30–80 kg (depending on roller material)

- Product width: 400–2500 mm (customizable)

- Safety configuration: End stop