Power Roller Turntable Conveyor

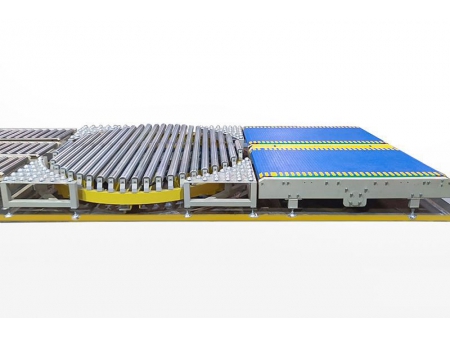

The power roller turntable conveyor system is a hub device in corrugated board conveying networks, which enables multi-directional diverting of board stacks and flexible path switching through a rotating platform. Its core includes a high-strength load-bearing turntable, a drive mechanism, and a positioning module capable of horizontal rotation from 0-360°. It connects with a cross-arranged conveyor to enable precise turning from longitudinal to transverse direction, as well as transitioning from straight lines to branch lines. This turntable system is suitable for corrugated line discharge, multi-line coordinated cardboard feeding, and downstream processes after printing, effectively addressing common limitations such as limited turning space and single-path routing in traditional conveying systems.

Features- Multi-Direction Flexible Diverting: Enable 360° stepless rotation to support docking with 4-way or 8-way conveying lines.

- Intelligent Dynamic Positioning: Equipped with a motor and a photoelectric encoder, closed-loop control to link with MES systems and respond in real time to takt adjustments.

- Stable Heavy-Load Transfer: Turntable uses a welded 16# channel-steel frame with a wear-resistant panel.

- Safety Coordination Protection: The turntable conveyor complied with CE safety standards, featuring obstacle avoidance and emergency-stop interlock functions, with optional photoelectric fencing to be installed in the rotation zone.

- Turntable diameter: 2000–5200 mm (customizable)

- Rotation angle: 0°–360° (electric control)

- Drive power: 1.5–5.5 kW (variable-frequency speed control motor)

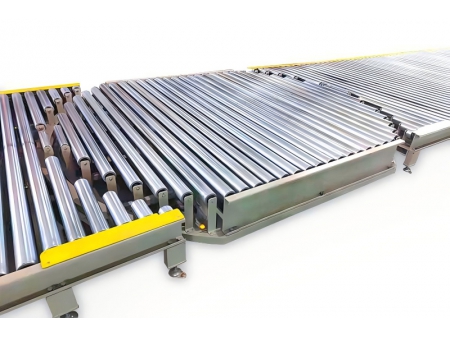

- Compatible conveyor: Roller conveyor/modular belt conveyor (optional)

- Safety configuration: Emergency stop button sound-and-light alarm