Tech Innovation

Technological innovation is the driving force of ECHOM. As a leading mold solutions provider in the industry, we have always been pushing the envelope when it comes to the technology behind our high-precision molds. Whether it is the comprehensive innovation of general production technologies or the research and development of unique design capabilities, we have been highly successful.

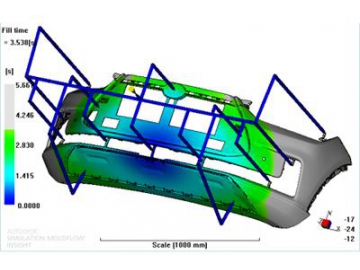

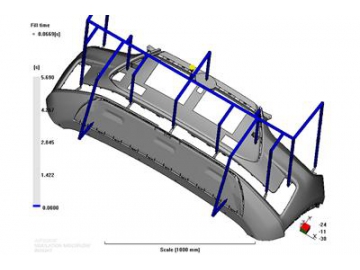

1. CAE simulation technology

CAE simulation technology forms an optimal injection plan by performing a simulation analysis that includes filling, pressure, cooling, warpage, and other injection molding factors using Auto Moldflow software. Applying this software analysis and support, we are able to add it to our rich experience and improve the quality and reliability of our molds for our customers.

2. Hot runner technology

While we study and master hot runner technology on our own, we have also made full use of professional support offered by such hot runner manufacturers as YUDO, INCOE, MOLD-MASTER, SYNVENTIVE, and HUSKY. Their services have allows us to provide customers with a wide range of customization options. We can deliver molds for high-quality manufacturing with professional grade hot runner technology coupled with sequential valve gating technology.

1. High gloss steam free spraying technology

We apply high gloss steam free spraying technology to achieve a high gloss piano finish texture on our products that is environmentally friendly, efficient, and affordable.

2. Silver free spraying technology

We apply silver free spraying technology to produce bumper trim panels (down), which can eliminate the traditional trim panel spraying process and allows for the bumpers to be directly installed on the car. It is an environmental friendly, highly efficient, and low cost solution.

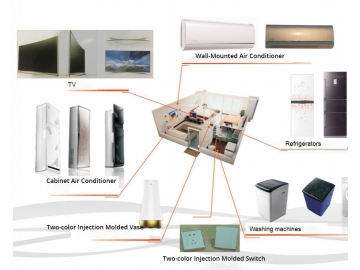

3. High gloss steam two-color technology

We apply a high gloss steam double-color technology to create a high gloss effect to meet the assembly requirements and improve the appearance of the product by allowing for different resins to be used.

4. Large stack mold technology

For flat products with large planned orders, we can use stack mold technology to reduce the energy consumption of equipment by 70% and increase the production efficiency by more than 60%. The greater the output, the more obvious the efficiency and cost advantages will be.