TIPS 6 Hole Spinning Spinneret for Manufacturing Hollow Fiber Membrane

1. Year: 2015

2. Country: China

3. Customer: Tianjin MOTIMO Membrane Technology

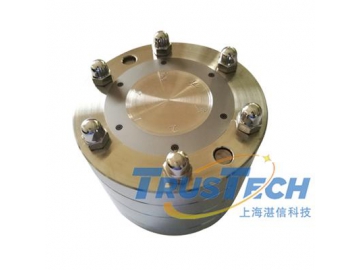

4. Product: TIPS 6 hole spinning spinneret for manufacturing hollow fiber membrane

5. Processing type: TIPS

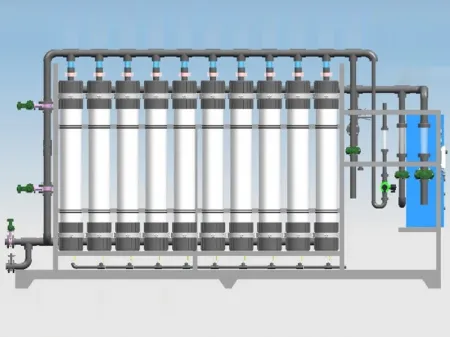

6. Application: Environment protection, Water purification

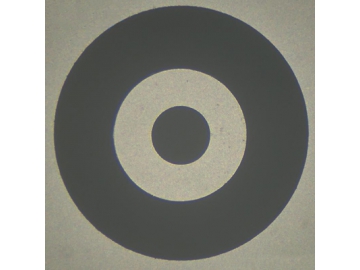

7. Specification: 2.6/1.6/1.2

8. Manufacturing capability: 2.600±0.002mm, 1.600±0.002mm, 1.200±0.004mm, assembly concentricity 0.005mm.

9. Spinneret material: Stainless steel

10. Applying material: PVDF (Polyvinylidene Fluoride)

Customer discovered a hollow fiber membrane spinneret needle tilt/eccentricity issue and a spinneret short life problem under the working conditions of 150-220℃, which lead to membrane flux unable to reach the design expectation, our high precision machining needle/spinneret solves this problem and achieved proper spinneret structure to reach satisfactory consistence of material flow among 6 holes by pre-product fluid analysis. We established long-term strategical cooperation with the customer, providing them with TIPS, NIPS – all kinds of spinnerets and also spinneret technology development plans for their new product development.

Applicable material

PVDF (Polyvinylidene Fluoride), PP(polypropylene), PE (polyethylene)

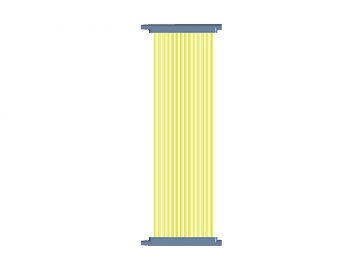

Trustech is a leading polymer fiber spinning spinneret manufacturer, by combined with advanced technology of fiber spinning process and equipment from Germany we can fabricate high quality spinneret, we can offer spinnerets used wet spinning, dry spinning, melt spinning for different fiber spinning process users, we have had clients who used our spinnerets to produce hollow fiber membrane for different filtration applications.

Index

wet spinning, melt spinning, drying spinning, gel spinning, spinning process