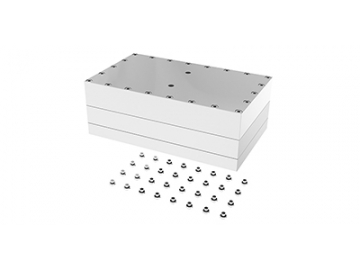

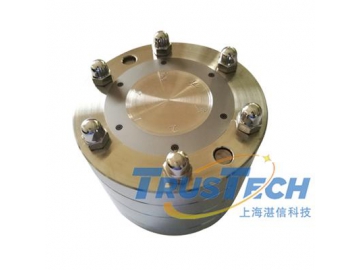

NIPS 128 Hole Spinning Spinneret for Manufacturing Hemodialysis Membrane Hollow Fiber Membrane

1. Year: 2017

2. Country: China

3. Customer: Lengthen

4. NIPS 128 hole spinning spinneret for manufacturing hemodialysis membrane hollow fiber membrane

5. Processing type: NIPS

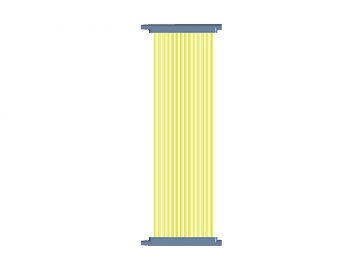

6. Application: Hemodialysis membrane

7. Specification: 0.5/0.28/0.15

8. Manufacturing capability: 0.500±0.002mm, 0.280±0.002mm, 0.150±0.004mm, assembly concentricity 0.003mm.

9. Spinneret material: Stainless steel

10. Applying material: PES (Polyethersulfone), PSF/PSU (Polysulfone),

Currently, the hemodialysis membrane spinneret is the highest-end product in the hollow fiber membrane spinneret industry. It represents the peak of the research and development capabilities of our company and the market in general. Customers use hemodialysis membrane spinneret to manufacture critical material hemodialysis membrane for artificial kidneys. Obviously, the requirements are high when it comes to the precision and reliability of our spinneret. The membrane diameter consistency requires hundreds and even thousands of holes. The customer signed a 3 year cooperative contract for 12,000 holes hollow fiber spinnerets for replacement and expansion.

Applicable materials

PVDF (Polyvinylidene Fluoride), CA(cellulose acetate), PVC(Polyvinyl chloride), PES(Polyethersulfone), PSF/PSU (Polysulfone), PA (Nylon, Polyamide), PAN (polyacrylonitrile)

Trustech is a leading polymer fiber spinning spinneret manufacturer, by combined with advanced technology of fiber spinning process and equipment from Germany we can fabricate high quality spinneret, we can offer spinnerets used wet spinning, dry spinning, melt spinning for different fiber spinning process users, we have had clients who used our spinnerets to produce hollow fiber membrane for different filtration applications.

Index

wet spinning, melt spinning, drying spinning, gel spinning, spinning process