High Speed 4 Lines Heat Sealing Cold Cutting Bag Making Machine

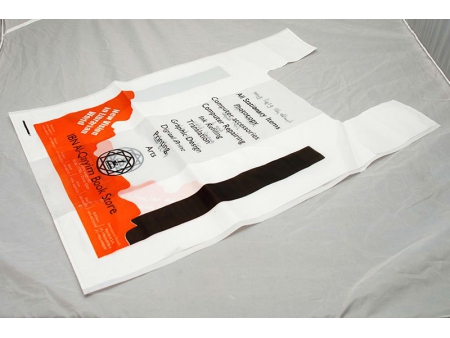

Suitable for making biodegradable plastic T-shirt shopping bags/flat garbage bags

This high speed 4 lines heat sealing and cold cutting bag making machine is primarily used to produce biodegradable and plastic T-shirt shopping bags, as well as flat bags. Taiwan-made frequency brake motor is used as its main motor, which helps to reduce electricity consumption and enables speed control more freely.

The unwinder with Taiwan design runs at the same speed as the main machine, and a longer service life is guaranteed due to its quality electric components from world's well-known brands. Not only does this plastic bag machine automatically save workers' time and energy, but it also ensures zero environmental damage.

| Model | RG-DL600 | RG-DL800 | RG-DL1000 | RG-DL1200 |

| Sealing and cutting width (mm) | 550*2 260*4 | 750*2 360*4 | 950*2 460*4 | 1150*2 560*4 |

| Sealing and cutting length (mm) | 1500 | 1500 | 1500 | 1500 |

| Bag making speed (pcs/min) | 240-480 | 240-480 | 240-480 | 240-480 |

| Power of motor (kW) | 1.5 | 1.5 | 1.5 | 2.2 |

| Weight (kg) | 1000 | 1300 | 1500 | 1700 |

| Dimension (m) | 4.8*1.4*1.9 | 4.8*1.4*1.9 | 4.8*1.6*1.9 | 4.8*1.8*1.9 |

This high speed 4 lines heat sealing and cold cutting bag making machine is typically used to make T-shirt shopping bags for supermarkets and retail stores, as well as flat bags for garbage disposal.

- Unwinder 370 W, A/C motor, inverter control

- Sealing Unit Sealing knife is made of high strength casting copper that has been subjected to heat treatment, ensuring it won't warp from heat

- Air Cooling System Controlled by Taiwan AirTAC electric valve

Air cooling method secures an increased sealing strength, without stretching - Cutting Unit The cutting knife is made of alloy steel materials, delivering prolonged service life

- Component Taiwan FOTEK solid state relay

Omron temperature controller

Schneider electric components

Panasonic photocell