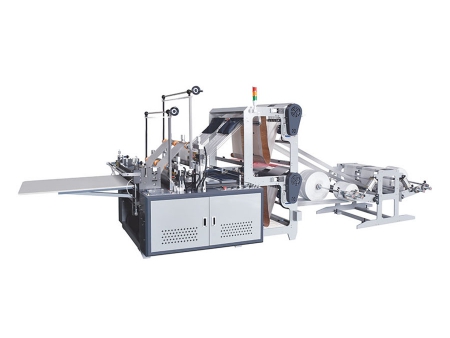

Automatic 4 Lines Biodegradable Bag Making Machine (New Design)

Request a Quote

Website: http://plastic-bagmachines.com/1-1-4-automatic-4-lines-biodegradable-bag-making-machine.html

Video

This biodegradable bag making machine is designed for producing vest bags and flat-opening bags made from eco-friendly materials. It features a Taiwan frequency conversion main motor that reduces energy consumption and allows smooth speed adjustment. The Taiwan-designed unwinder operates in perfect sync with the main machine for improved performance. Built with high-quality electrical components from trusted global brands, the machine ensures long-lasting reliability. Fully automatic operation reduces labor requirements and supports environmentally responsible production.

Bag Samples

- Supermarket Shopping Bags

- Supermarket Shopping Bags

- Household and Hotel Garbage Bags

- Household and Hotel Garbage Bags

Technical Parameters

| Model | TP-DLA800 | TP-DLA1000 | TP-DLA1200 |

| Sealing and cutting width (mm) | 750 x 2, 360 x 4 | 950 x 2, 460 x 4 | 1150 x 2, 560 x 4 |

| Sealing and cutting length (mm) | 1500 | 1500 | 1500 |

| Bag making speed (pcs/min) | 280 - 560 | 280 - 560 | 280 - 560 |

| Power of motor (kW) | 1.5 | 1.5 | 2.2 |

| Weight (kg) | 1500 | 1600 | 1700 |

| Dimension (L×W×H) (m) | 4.8 x 1.4 x 1.9 | 4.8 x 1.6 x 1.9 | 4.8 x 1.8 x 1.9 |

Details

-

- Unwinder with Auto Loading

Features an automatic loading system that reduces manual labor and improves operational efficiency.

- Unwinder with Auto Loading

-

- High Quality Unwinder Motor

Equipped with an AC motor for stable performance

Delta inverter for precise speed control

Taiwan brand components ensure long service life

- High Quality Unwinder Motor

-

- Unwinder Structure

Air-controlled rubber roller system allows easy handling by operators.

Built with a 12mm steel plate base for stable machine operation.

- Unwinder Structure

-

- Rubber Roller Design

Designed to run 4 lines of small bags with separate rollers or 2 lines of larger bags with a connected roller—flexible and efficient.

- Rubber Roller Design

-

- New Transmission System

Replaces the traditional chain with a timing belt to eliminate internal machine noise. Includes an extra belt for future maintenance.

- New Transmission System

-

- Enhanced Cam for Sealing Knife

Upgraded cam design increases bag making speed from 120 pcs/min to 140 pcs/min, significantly boosting production capacity.

- Enhanced Cam for Sealing Knife

-

- Reinforced Sealing Bar

Uses a 50×50 mm aluminum bar to secure the sealing knife for stronger pressure and improved sealing quality.

- Reinforced Sealing Bar

-

- Oil Cup Lubrication System

An integrated oil cup continuously lubricates the sealing shaft, reducing noise and extending machine life.

- Oil Cup Lubrication System

-

- Optimized Cutting Knife Design

Made from durable alloy steel with a spring-type configuration that minimizes cutting noise and extends blade lifespan./span>

- Optimized Cutting Knife Design

-

- Advanced Electric Control System

Main motor managed by Delta inverter, with Fotek relay and Schneider electric parts for stable and reliable operation.

- Advanced Electric Control System